Introduction

In modern precision industries, cleanliness is not just a standard—it is a necessity that directly impacts product quality, manufacturing stability, and operational efficiency. Among a variety of cleaning materials, Cleanroom Wipers have become the undisputed choice for many leading enterprises, hailed as the "ceiling of industrial cleaning." This page explores why cleanroom wipers dominate the market, their applications across industries, and how choosing the right wiper impacts your bottom line.

What is a Cleanroom Wiper?

Cleanroom Wipers are specially engineered wiping materials designed for sensitive environments such as cleanrooms, laboratories, and precision manufacturing facilities. Unlike ordinary tissues or cloths, cleanroom wipers are made using advanced composite technologies, combining fiber pulp and polymer materials through hydroentanglement non-woven processes.

This results in:

1)Ultra-low particle shedding

2)High liquid absorption—up to 6 times its weight

3)Compliance with Class 100 Cleanroom Standards

4)Superior strength and durability

Why Are Cleanroom Wipers Critical in Precision Industries?

Cleanroom wipers are far beyond conventional cleaning materials due to their physical and chemical stability, making them indispensable in environments where micro-level contamination leads to production defects or safety risks.

1. Ultra-Low Dust and Fiber Shedding

Laboratory tests prove cleanroom wipers achieve Class 100 Cleanroom Levels, with minimal dust or fiber release, preventing secondary contamination.

2. High Absorbency

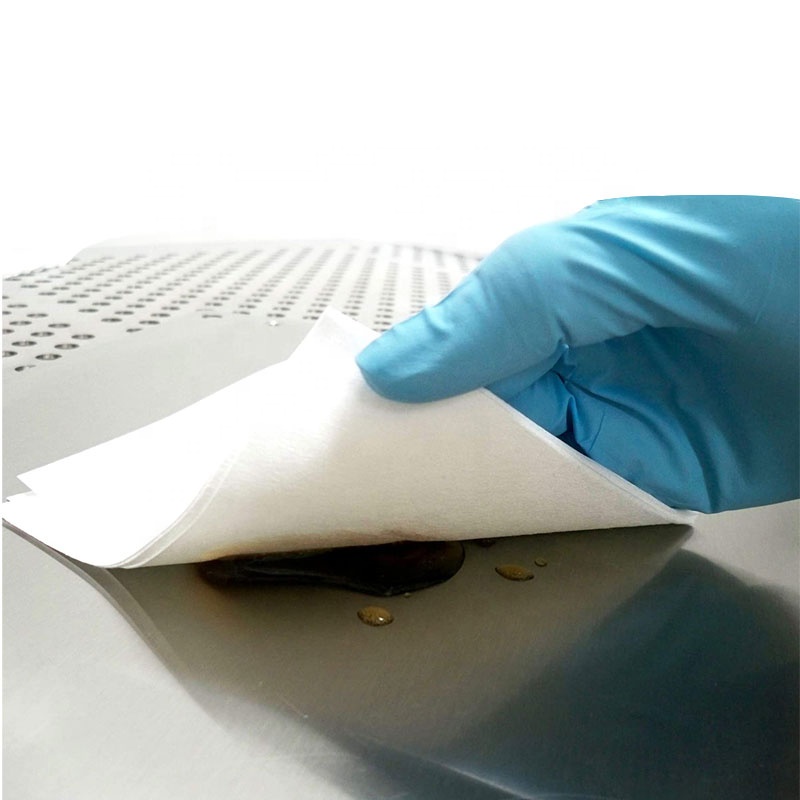

Their unique composition allows quick absorption of liquid—oil, water, solvents—making them ideal for removing residues without smearing or leaving lint.

3. Protection for Precision Components

The soft, fine texture prevents scratches and abrasions on sensitive surfaces, extending the lifespan of precision instruments.

Multi-Industry Application Scenarios

| Application | Cleanroom Wiper Advantages | Real-world Impact |

| Precision Instruments | Ultra-low fiber shedding, gentle texture | Prevents scratches, maintains accuracy and stability of high-precision components |

| Automotive Paint Shops | Absorbs liquids up to 6x its weight | Quickly removes water and oil before painting, improving coating uniformity and durability |

| Food Processing Lines | Food-grade safe, free from harmful additives | Efficient oil absorption ensures hygiene and safety, preventing cross-contamination |

| Class 100 Cleanrooms | Meets strict cleanroom standards, ultra-low shedding | Prevents contamination during cleaning of tools, floors, and surfaces, maintaining production standards |

Economic Value Behind the Cost

Some businesses hesitate due to the price—cleanroom wipers often cost 5 times more than ordinary wipes. However, industry data proves their cost-efficiency .

Case Study:

A leading auto parts factory reported the following after replacing traditional wipes with cleanroom wipers in their spray booth:

Cleanroom Wiper Selection Guide - Avoid These Common Pitfalls

Some businesses hesitate due to the price—cleanroom wipers often cost 5 times more than ordinary wipes. However, industry data proves their cost-efficiency .

Case Study:

A leading auto parts factory reported the following after replacing traditional wipes with cleanroom wipers in their spray booth:

Technical Advantages of Cleanroom Wipers

Hydroentangled Fiber Structure

Strong bonding without glue or chemicals

Class 100 Certification

Suitable for semiconductor, pharmaceutical, and aerospace industries

Non-abrasive Texture

Prevents micro-scratches during use

High Compatibility

Safe with solvents, alcohols, and chemicals

Cleanroom Wipers -

The Preferred Choice for Industrial Leaders

With technology-driven design and unbeatable performance, cleanroom wipers have become the first choice for enterprises demanding precision and efficiency. Their multi-industry applications, cost-effectiveness, and strong cleaning ability make them a strategic investment.

Are you ready to upgrade your cleaning materials and optimize your production line? Contact us today for expert guidance and sample testing!

English

English