Introduction to ESD Wrist Strap

In the electronics manufacturing and precision instrument maintenance industries, the ESD (Electrostatic Discharge) Wrist Strap is a critical tool. Designed to prevent static electricity damage to sensitive electronic components, the ESD wrist strap is a simple yet effective solution for ensuring the safety of both personnel and electronic devices. Without adequate ESD protection, static buildup can cause irreversible damage to microprocessors, integrated circuits, and other components, resulting in costly failures and operational downtime.

Product Overview and Components

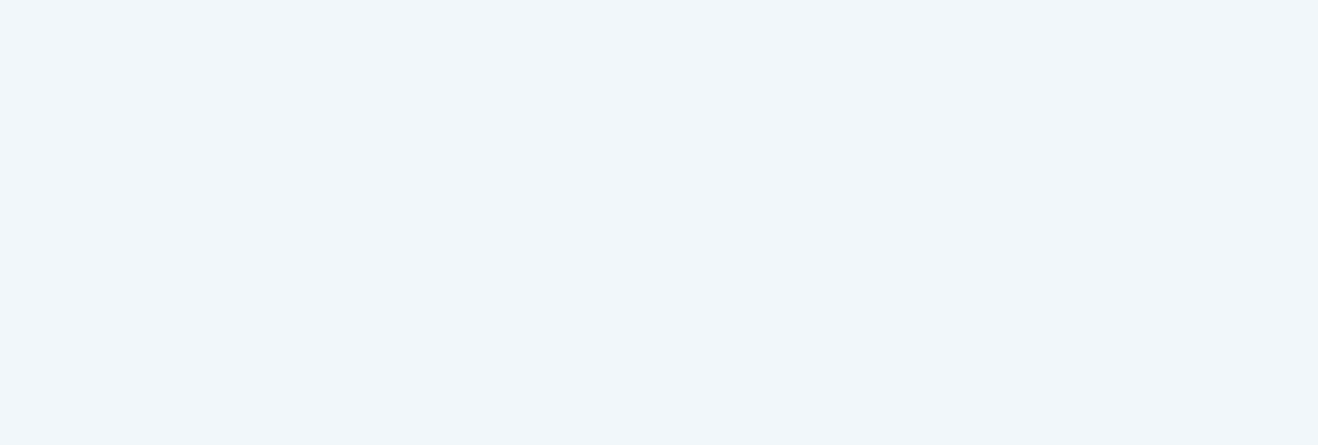

An ESD wrist strap typically consists of:

Conductive Elastic Band: Made of special conductive fibers that ensure comfortable wear and effective discharge.

Adjustable Buckle: Allows a snug fit for different wrist sizes, enhancing both comfort and conductivity.

Coiled Cord (Spring End): Provides flexibility during operation while maintaining a secure connection.

Grounding Wire: Safely transfers static electricity from the human body to the ground.

Alligator Clip or Banana Plug: Connects the grounding wire securely to an ESD-safe surface.

The ESD wrist strap is simple to use: wear the strap, attach the grounding wire, and connect to a proper ground point. This setup ensures that any static charge accumulated on the body is safely discharged.

How ESD Wrist Straps Work

Static Electricity Discharge

Working Principle: As the human body comes into contact with electronic devices, static electricity is transferred through the wrist strap and grounding wire, safely discharging to the ground.

Importance: Static discharges as low as 10 volts can damage sensitive electronic parts. By using an ESD wrist strap, these risks are significantly reduced, maintaining the integrity of components during assembly or repair.

Continuous Monitoring for Safety

Working Principle: Advanced wrist straps connect to monitoring systems that measure resistance in real-time. If the circuit is broken or resistance is outside the safe range, an alarm triggers immediately.

Importance: Continuous monitoring is crucial for long-duration tasks. It prevents unnoticed disconnection or degradation in the strap's conductive properties, ensuring 24/7 protection against ESD hazards.

Advantages of ESD Wrist Strap

Protects Sensitive Components

Microprocessors, ICs, and memory chips are highly vulnerable to static damage. Using an ESD wrist strap prevents invisible static discharges that could shorten component lifespan or cause latent failures.

Ensures Operator Safety

The ESD wrist strap is designed with safety in mind. It prevents operators from receiving electric shocks caused by unintentional static buildup, especially in high-risk environments like semiconductor plants and cleanrooms.

Compliance with Industry Standards

Many industries require strict adherence to ESD control standards such as ANSI/ESD S20.20 and IEC 61340. ESD wrist straps are fundamental to meeting these standards and passing quality audits, certifications, and client inspections.

Reduces Equipment Failure and Data Loss Risks

In data centers, telecom hubs, and laboratories, even minor static discharges can cause hardware failures or data corruption. Using wrist straps minimizes electromagnetic interference (EMI), improving operational reliability.

Enhances Product Quality and Manufacturing Yield

Proper static control translates to fewer production defects, reduced rework, and increased yield. ESD wrist straps are a low-cost investment with a high impact on quality control.

Applications of ESD Wrist Straps

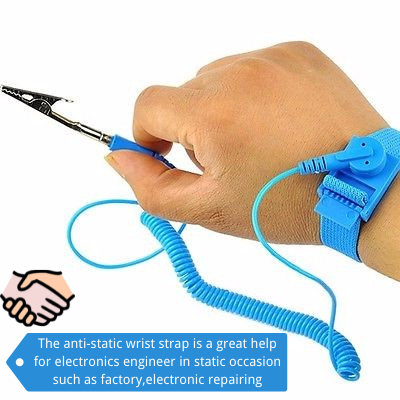

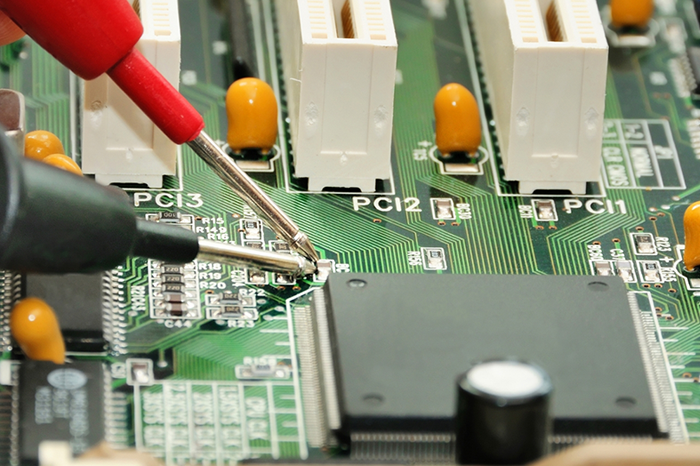

Electronics Manufacturing & Assembly

PCB Repair & Rework Stations

Precision Instrument Servicing

Semiconductor Plants & Clean Rooms

Data Centers & Server Rooms

Telecommunications Equipment Maintenance

Choosing the Right ESD Wrist Strap

When selecting an ESD wrist strap, consider the following factors:

Material Quality: Durable, hypoallergenic, and conductive materials ensure long-term reliability and comfort.

Adjustability: A good fit improves user comfort and consistent contact.

Cord Length & Flexibility: Coiled cords provide freedom of movement without risking disconnection.

Resistance Value: Ideal wrist straps have a resistance range of 1MΩ to 10MΩ, balancing safety and effective discharge.

Monitoring Compatibility: For critical environments, choose straps compatible with continuous monitoring systems.

Frequently Asked Questions (FAQs)

-

Q: Can I use an ESD wrist strap without grounding?

A: No. Without proper grounding, the wrist strap cannot dissipate static electricity, making it ineffective.

-

Q: How often should ESD wrist straps be tested?

A: Industry best practice recommends testing straps daily before use or according to your facility's ESD control program.

-

Q: Are wireless ESD wrist straps effective?

A: Wireless ESD wrist straps often lack consistent performance and are generally not recommended for professional electronic assembly tasks.

Best Practices

for Using

ESD Wrist Straps

Always inspect the strap for wear or damage before use.

Replace damaged cords or connectors immediately.

Ensure proper connection to a verified ground point.

Test wrist straps regularly with an ESD tester.

Train all personnel in proper ESD procedures.

Why Invest in Quality ESD Wrist Straps?

The ESD wrist strap is not just a tool but a critical component of any professional ESD control program. It safeguards valuable components, ensures operator safety, and helps companies comply with international quality standards. Investing in high-quality ESD wrist straps enhances productivity, reduces losses, and builds a solid reputation for reliability and excellence in the electronics industry.

For bulk orders, customized solutions, or expert consultations on selecting the right ESD wrist strap for your business, contact us today.

English

English