| Material: | Type: |

| Plastic | Tray packaging |

| Plastic Type: | material: |

| PP | eco-friendly |

| Process Type: | usage: |

| Blister | packing and transport |

| Custom Order: | Color: |

| Accept | Customized |

| Place of Origin: | Size: |

| Guangdong, China | Customized Size |

| Brand Name: | Logo: |

| ksm | Customer's Logo |

| Model Number: | Thickness: |

| ksmt-t0101 | 0.25mm~1.5mm |

| Use: | Certificate: |

| Electronic | ISO9001:2008 |

| Blister trays: | Plastic trays: |

| ESD tray | PP tray |

LEENOL

| Availability: | |

|---|---|

| Quantity: | |

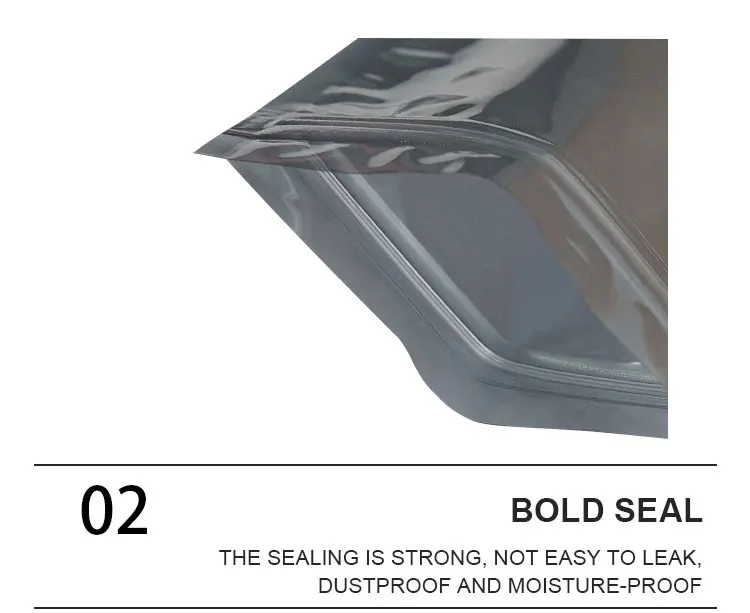

This Aluminum Foil Shielding Bag is engineered for vacuum packaging electronic components. It features a multi-layer structure that creates a Faraday Cage effect against static while providing a hermetic seal against moisture and oxygen, meeting strict industrial packaging standards.

Multi-Layer Construction: Combines an outer static-dissipative layer, a middle aluminum foil layer for shielding, and an inner poly layer for sealing.

Superior Moisture Barrier: With a Moisture Vapor Transmission Rate (MVTR) , it creates an airtight environment essential for preventing "pop-corning" during solder reflow.

High Puncture Resistance: The >18lbs puncture strength ensures the bag won't be pierced by sharp component leads or tray corners during vacuum sealing.

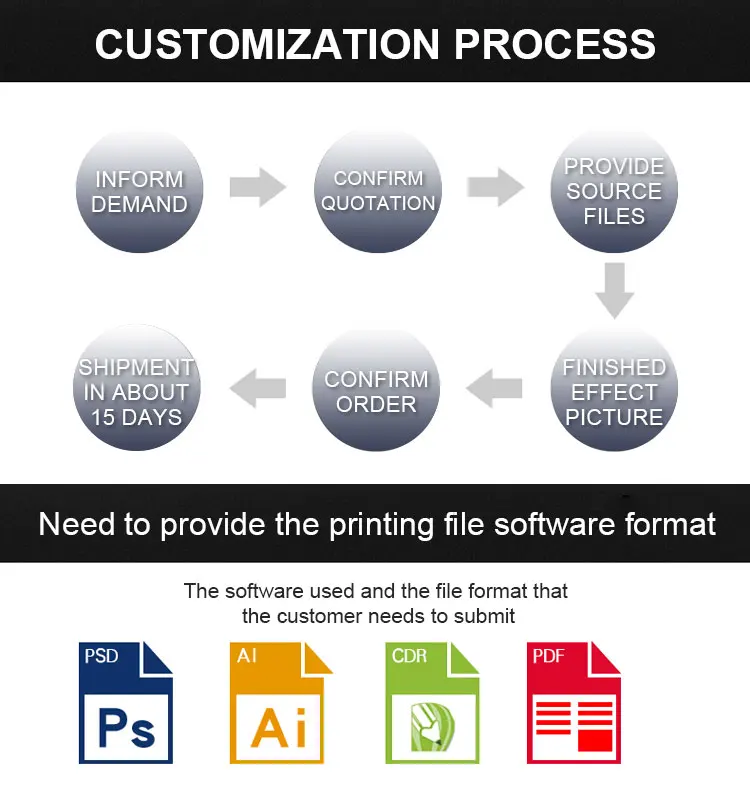

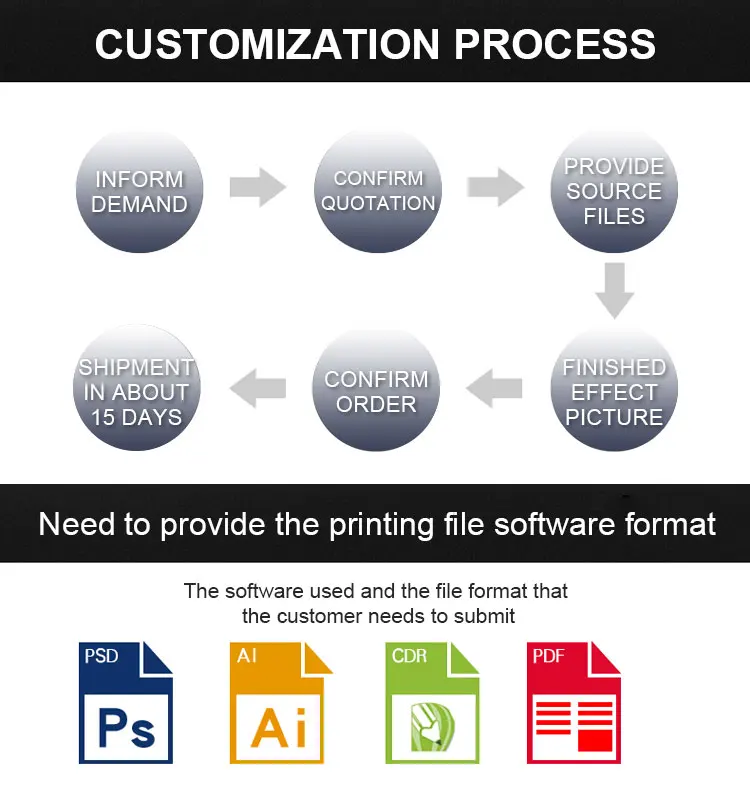

Customizable Branding: Supports Screen Printing for adding your company logo, ESD warning symbols, or lot tracking information directly onto the bag surface.

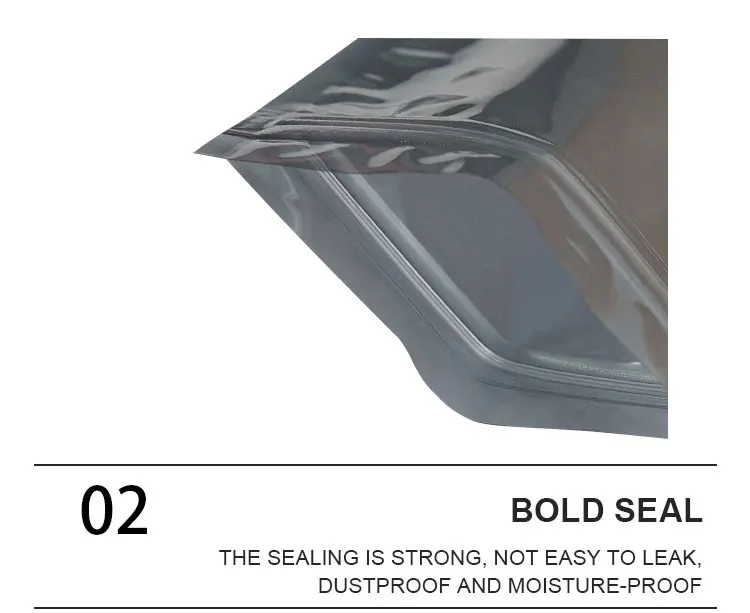

Heat Seal Compatible: Designed for secure heat sealing to maintain a vacuum environment (Vacuum sealing is recommended for maximum moisture protection).

| Material: | Aluminum Foil |

| Feature: | ANTISTATIC |

| Surface Handling: | Screen Printing |

| Sealing & Handle: | Spout Top |

| Custom Order: | Accept |

| Thickness: | 0.1mm |

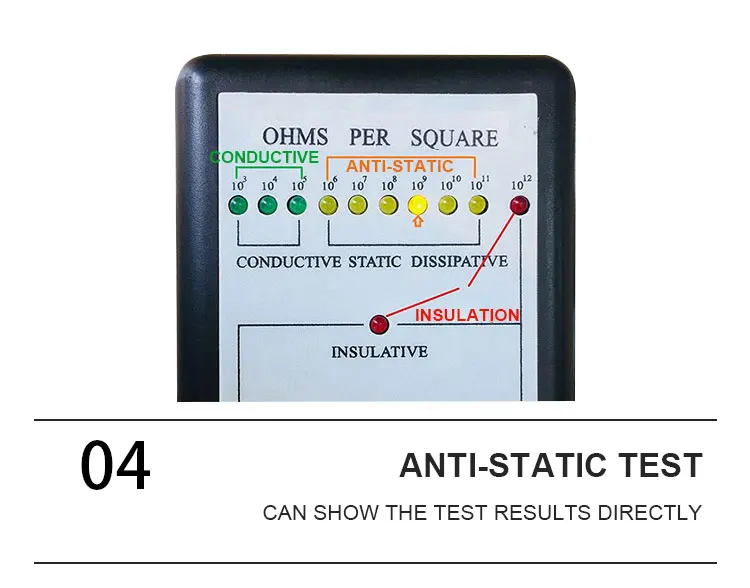

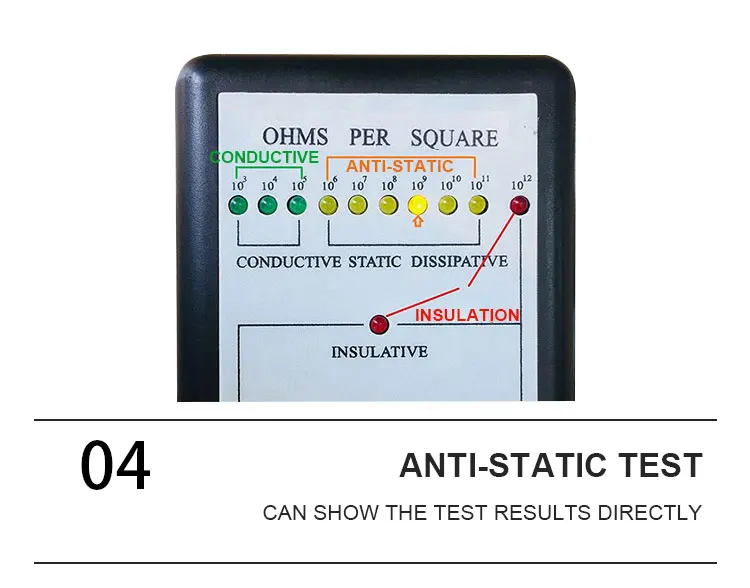

| static decay: | <0.05s |

| Surface resistance: | 10e8-10e11 ohms |

| puncture resistance: | >18lbs |

| MVTR | <=0.005 |

Dual Protection: Solves two problems at once: it shields components from Electrostatic Discharge (ESD) fields and blocks external moisture/oxygen ingress.

Vacuum Ready: The 0.1mm thickness and strong seal integrity make it perfect for vacuum packing, which is the industry standard for long-term component storage.

Reduced Rejects: By keeping components dry, it prevents micro-cracking and delamination during the soldering process, significantly lowering defect rates.

Flexible Customization: Whether you need specific sizes for large PCB panels or custom printing for brand consistency, we accept custom orders to fit your workflow.

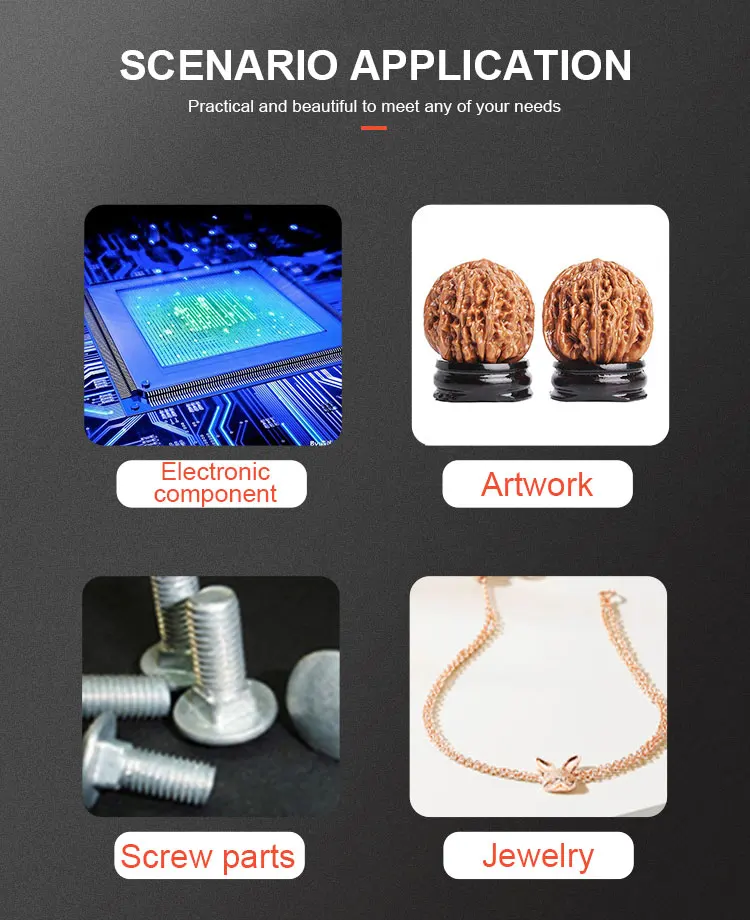

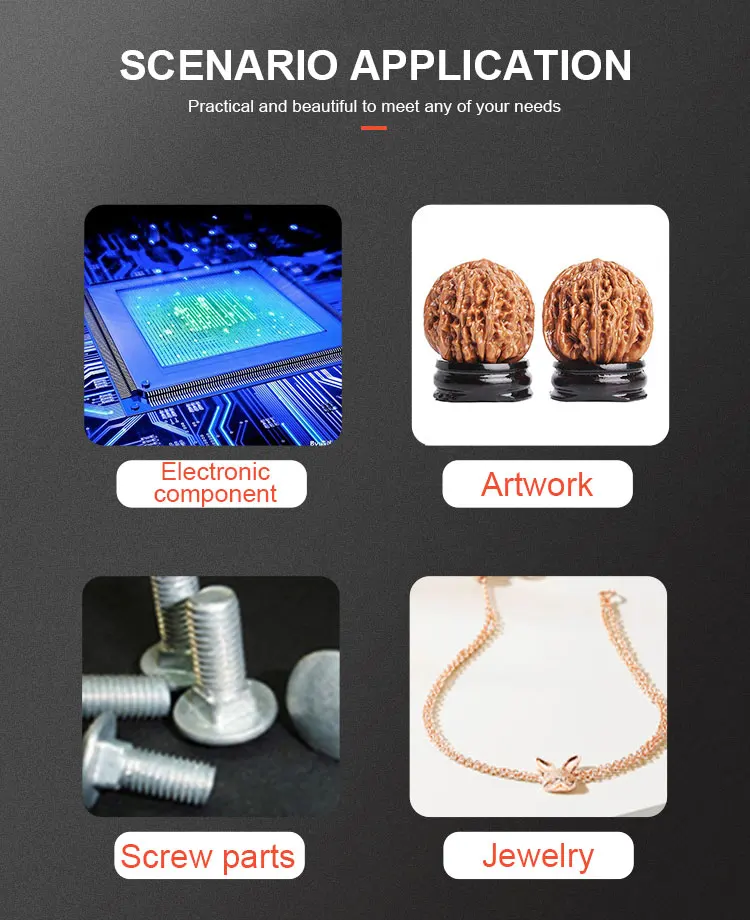

These bags are critical for packaging moisture-sensitive level (MSL) components:

Semiconductors: ICs, BGAs, and FPGS chips.

PCB Assemblies: Finished or semi-finished circuit boards.

Precision Parts: Hard disk drives and optical lenses.

SMT Manufacturing: Storage of reels and trays that have been removed from original packaging.

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packa

ESD Bag Antistatic Plastic Shielding Bag For Component Pack

This Aluminum Foil Shielding Bag is engineered for vacuum packaging electronic components. It features a multi-layer structure that creates a Faraday Cage effect against static while providing a hermetic seal against moisture and oxygen, meeting strict industrial packaging standards.

Multi-Layer Construction: Combines an outer static-dissipative layer, a middle aluminum foil layer for shielding, and an inner poly layer for sealing.

Superior Moisture Barrier: With a Moisture Vapor Transmission Rate (MVTR) , it creates an airtight environment essential for preventing "pop-corning" during solder reflow.

High Puncture Resistance: The >18lbs puncture strength ensures the bag won't be pierced by sharp component leads or tray corners during vacuum sealing.

Customizable Branding: Supports Screen Printing for adding your company logo, ESD warning symbols, or lot tracking information directly onto the bag surface.

Heat Seal Compatible: Designed for secure heat sealing to maintain a vacuum environment (Vacuum sealing is recommended for maximum moisture protection).

| Material: | Aluminum Foil |

| Feature: | ANTISTATIC |

| Surface Handling: | Screen Printing |

| Sealing & Handle: | Spout Top |

| Custom Order: | Accept |

| Thickness: | 0.1mm |

| static decay: | <0.05s |

| Surface resistance: | 10e8-10e11 ohms |

| puncture resistance: | >18lbs |

| MVTR | <=0.005 |

Dual Protection: Solves two problems at once: it shields components from Electrostatic Discharge (ESD) fields and blocks external moisture/oxygen ingress.

Vacuum Ready: The 0.1mm thickness and strong seal integrity make it perfect for vacuum packing, which is the industry standard for long-term component storage.

Reduced Rejects: By keeping components dry, it prevents micro-cracking and delamination during the soldering process, significantly lowering defect rates.

Flexible Customization: Whether you need specific sizes for large PCB panels or custom printing for brand consistency, we accept custom orders to fit your workflow.

These bags are critical for packaging moisture-sensitive level (MSL) components:

Semiconductors: ICs, BGAs, and FPGS chips.

PCB Assemblies: Finished or semi-finished circuit boards.

Precision Parts: Hard disk drives and optical lenses.

SMT Manufacturing: Storage of reels and trays that have been removed from original packaging.

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packaging

ESD Bag Antistatic Plastic Shielding Bag For Component Packa

ESD Bag Antistatic Plastic Shielding Bag For Component Pack