| Material: | Type: |

| Plastic | Tray packaging |

| Plastic Type: | material: |

| PP | eco-friendly |

| Process Type: | usage: |

| Blister | packing and transport |

| Custom Order: | Color: |

| Accept | Customized |

| Place of Origin: | Size: |

| Guangdong, China | Customized Size |

| Brand Name: | Logo: |

| ksm | Customer's Logo |

| Model Number: | Thickness: |

| ksmt-t0101 | 0.25mm~1.5mm |

| Use: | Certificate: |

| Electronic | ISO9001:2008 |

| Blister trays: | Plastic trays: |

| ESD tray | PP tray |

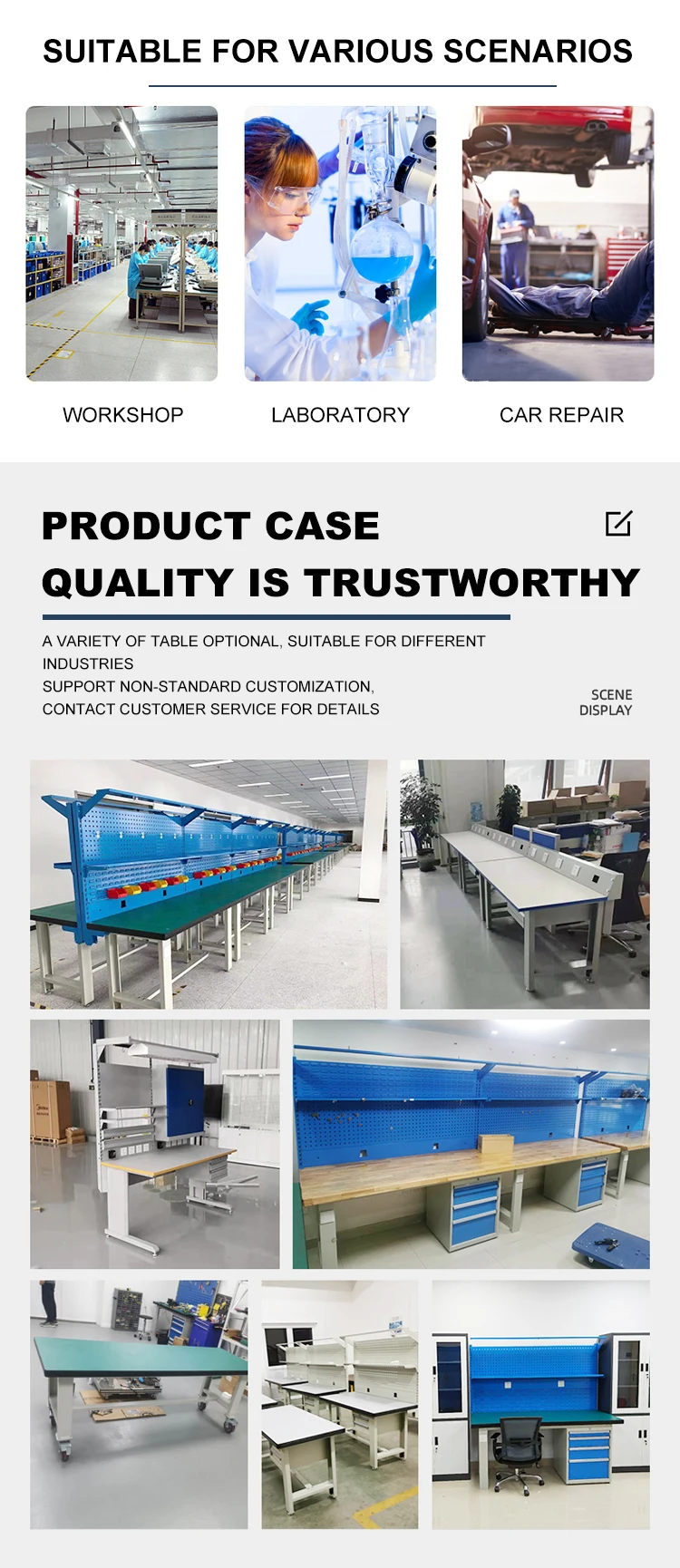

Designed as the cornerstone of ESD Protected Areas (EPAs), our Customized SMT Production Stainless Steel Waterproof ESD Workbench provides a controlled environment for surface mount technology (SMT) manufacturing.

LN20

LEENOL

| Availability: | |

|---|---|

| Quantity: | |

*Optimized support structures use high pressure spraying of refined unfired metal, ensuring beautiful results every time.

*The feature of integral ESD could make the threat of static electricity to your products a thing of the past.

Constructed from 304-grade stainless steel, this workbench features a waterproof surface with a surface resistance of 10^6 - 10^8 Ω, fully compliant with ESD S20.20 standards—the global benchmark for electrostatic control in electronics manufacturing. Its modular design supports integration with ionizers, grounding straps, and tool holders, creating a comprehensive ESD protection ecosystem.

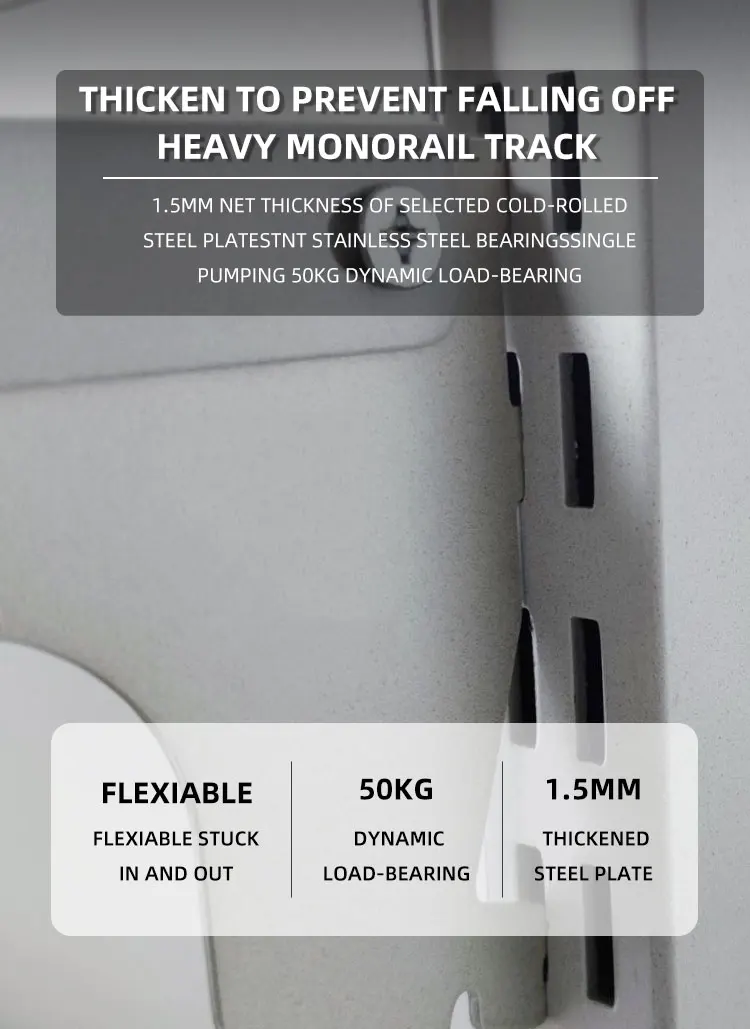

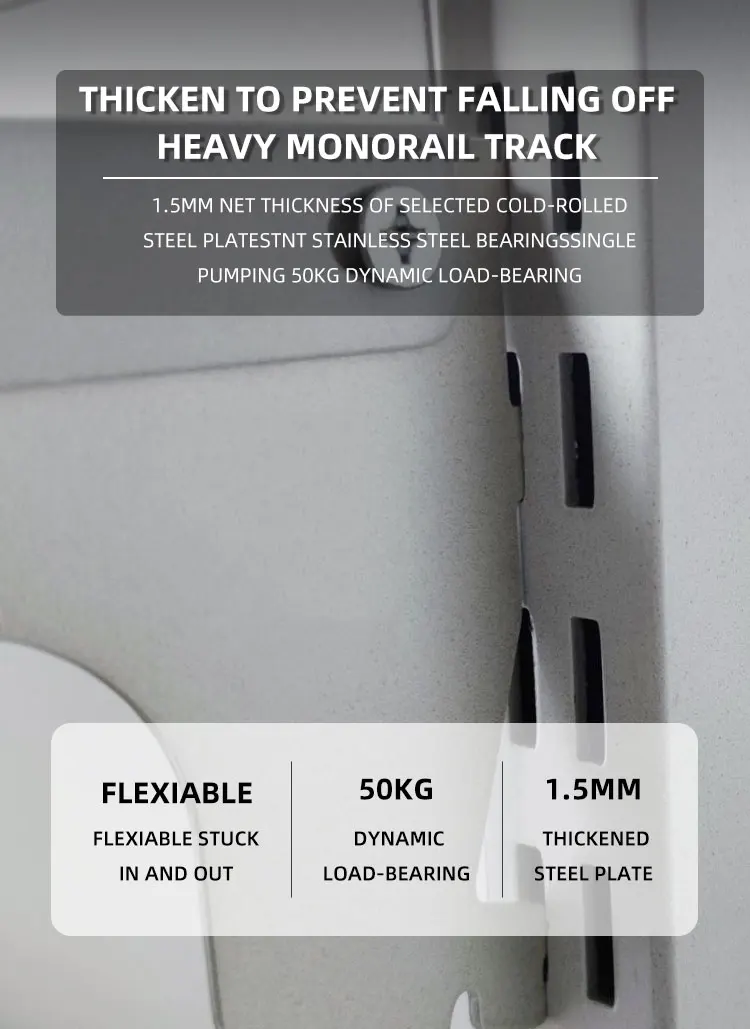

The 1.5mm thick stainless steel resistant to corrosion and chemical cleaning agents maintains consistent grounding resistance of <1 Ω through a dedicated 4mm grounding port, ensuring rapid charge dissipation to earth.

IP65-rated waterproof construction allows thorough cleaning with industrial detergents without compromising ESD performance. Temperature resistance from -20℃ to 80℃ ensures stability in varying factory environments.

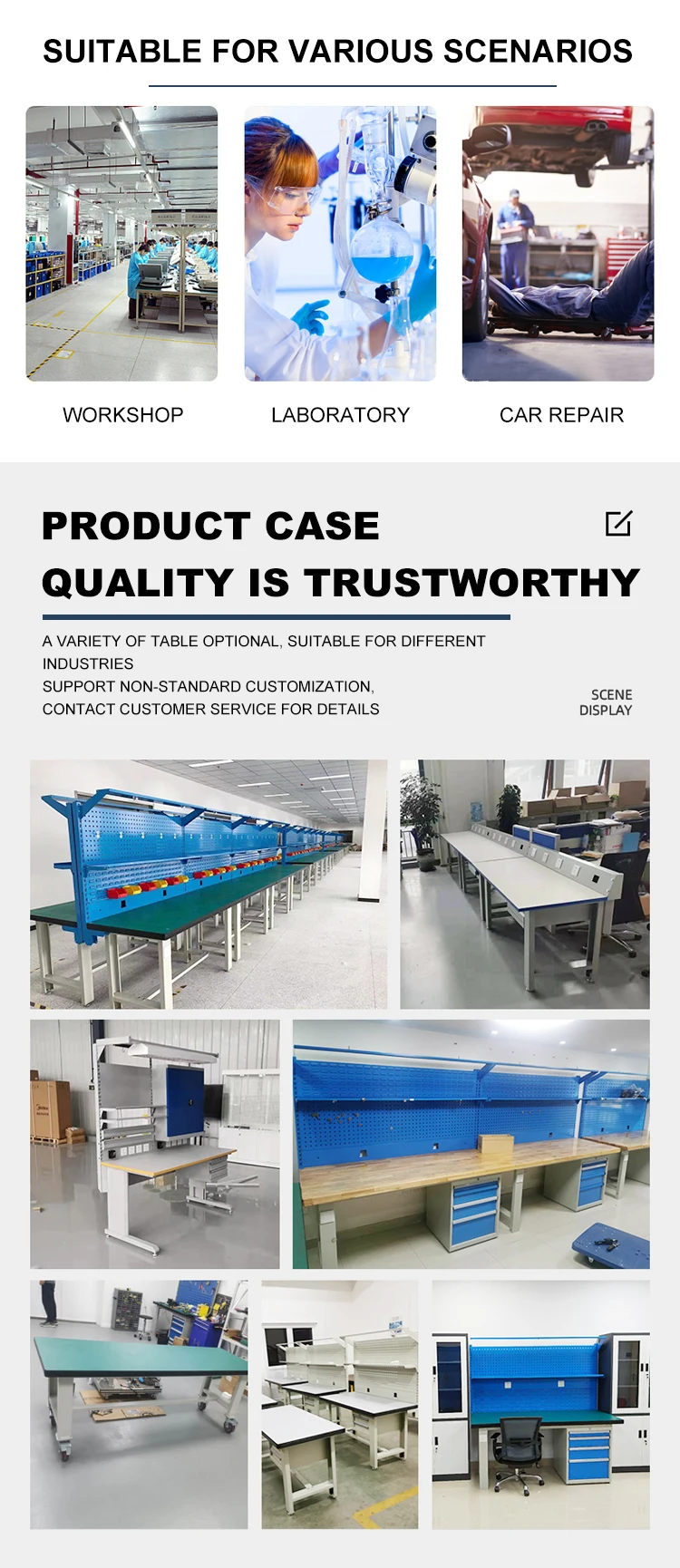

Essential for controlled manufacturing environments:

SMT Assembly Lines: PCB assembly stations requiring constant ESD monitoring

Electronics Testing Labs: Precision measurement areas for sensitive components

Medical Device Manufacturing: Cleanroom-compatible workstations for implantable electronics production

How often should grounding continuity be tested?

Following ESD S20.20 guidelines, we recommend daily resistance testing using a megohmmeter, with formal certification audits every 6 months.

Can the workbench be integrated with existing ESD systems?

Yes, it features standard 4mm banana jack connectors compatible with most EPA monitoring systems and grounding mats.

What is the warranty period for ESD performance?

We guarantee ESD properties will remain within specification for 5 years under normal operating conditions, with annual calibration services available.

| Accessory name | Quantity |

| Heavy fixed table support 1500*750mm | 1 |

| wear resistant polymer table top 1530*750*50mm | 1 |

| Upright Accessory Frame 2M750*1359mm | 1 |

| Imported double ESD up Shelf, gray,M1530*380mm+ Shelf bracket(3) | 1 |

| ESD adjustable shelf M750*650+ single-face bracket | 1 |

| Oblique Light Support bracket 2M750*380MM+ slide hook | 1 |

| Prism light 2*30W | 1 |

| Suspension rail for picking Bins M750mm | 2 |

| ESD movable cabinet MV1 400*560*650mm | 1 |

| Power channel M750 | 1 |

| SPECIFICATIONS FOR DETALL STANDARD TABLE | ||

| Size | Length | 1200/1530/1830(mm) |

| Deepth | 600/750/900(mm) | |

| Height | 785mm (table top to ground) 670-1120 (adjustable type) | |

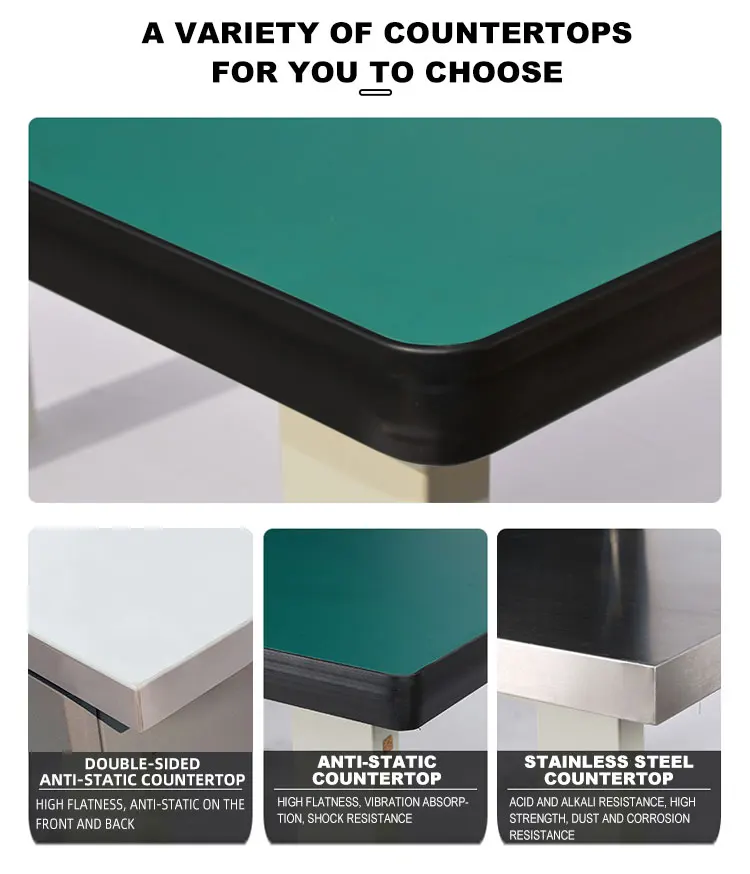

| Main performance parameters | ESD performance parameters | metal surface: 105 - 1010 Laminate surface: 106 - 1010 |

| Static weight loading | 300kg - light duty type 500kg - standard duty type 800kg - heavy duty type | |

*Optimized support structures use high pressure spraying of refined unfired metal, ensuring beautiful results every time.

*The feature of integral ESD could make the threat of static electricity to your products a thing of the past.

Constructed from 304-grade stainless steel, this workbench features a waterproof surface with a surface resistance of 10^6 - 10^8 Ω, fully compliant with ESD S20.20 standards—the global benchmark for electrostatic control in electronics manufacturing. Its modular design supports integration with ionizers, grounding straps, and tool holders, creating a comprehensive ESD protection ecosystem.

The 1.5mm thick stainless steel resistant to corrosion and chemical cleaning agents maintains consistent grounding resistance of <1 Ω through a dedicated 4mm grounding port, ensuring rapid charge dissipation to earth.

IP65-rated waterproof construction allows thorough cleaning with industrial detergents without compromising ESD performance. Temperature resistance from -20℃ to 80℃ ensures stability in varying factory environments.

Essential for controlled manufacturing environments:

SMT Assembly Lines: PCB assembly stations requiring constant ESD monitoring

Electronics Testing Labs: Precision measurement areas for sensitive components

Medical Device Manufacturing: Cleanroom-compatible workstations for implantable electronics production

How often should grounding continuity be tested?

Following ESD S20.20 guidelines, we recommend daily resistance testing using a megohmmeter, with formal certification audits every 6 months.

Can the workbench be integrated with existing ESD systems?

Yes, it features standard 4mm banana jack connectors compatible with most EPA monitoring systems and grounding mats.

What is the warranty period for ESD performance?

We guarantee ESD properties will remain within specification for 5 years under normal operating conditions, with annual calibration services available.

| Accessory name | Quantity |

| Heavy fixed table support 1500*750mm | 1 |

| wear resistant polymer table top 1530*750*50mm | 1 |

| Upright Accessory Frame 2M750*1359mm | 1 |

| Imported double ESD up Shelf, gray,M1530*380mm+ Shelf bracket(3) | 1 |

| ESD adjustable shelf M750*650+ single-face bracket | 1 |

| Oblique Light Support bracket 2M750*380MM+ slide hook | 1 |

| Prism light 2*30W | 1 |

| Suspension rail for picking Bins M750mm | 2 |

| ESD movable cabinet MV1 400*560*650mm | 1 |

| Power channel M750 | 1 |

| SPECIFICATIONS FOR DETALL STANDARD TABLE | ||

| Size | Length | 1200/1530/1830(mm) |

| Deepth | 600/750/900(mm) | |

| Height | 785mm (table top to ground) 670-1120 (adjustable type) | |

| Main performance parameters | ESD performance parameters | metal surface: 105 - 1010 Laminate surface: 106 - 1010 |

| Static weight loading | 300kg - light duty type 500kg - standard duty type 800kg - heavy duty type | |