Views: 286 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

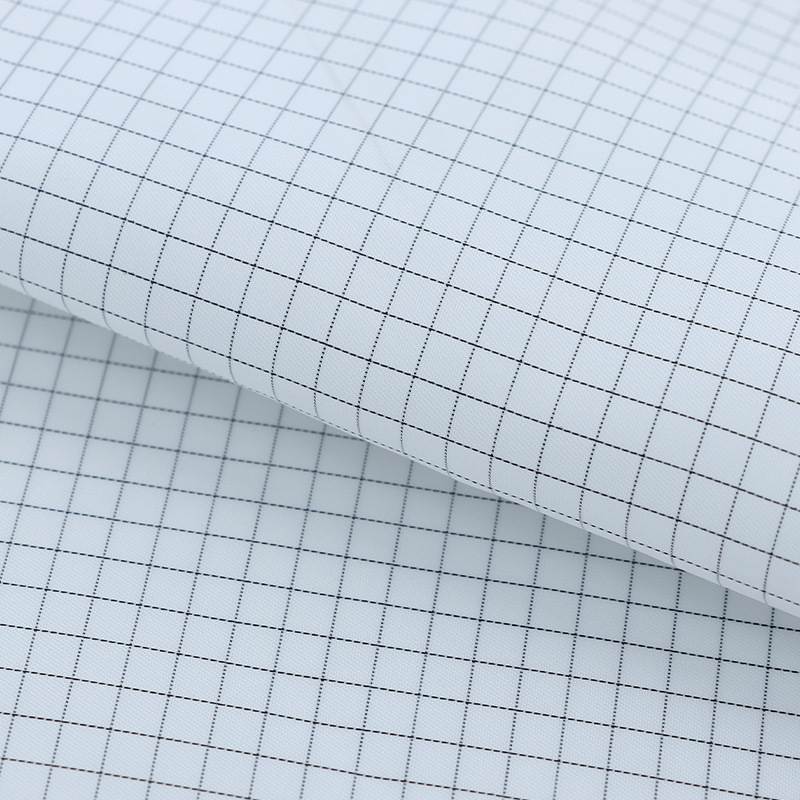

Electrostatic discharge (ESD) is a silent, yet highly destructive force that can cause significant damage to sensitive electronic equipment. For industries dealing with delicate components and machinery, controlling ESD is crucial. One of the most effective ways to manage static electricity is through the use of ESD fabric. This article will explore everything you need to know about ESD fabric—what it is, how it works, its various types, key properties, and the wide range of applications across industries.

Electrostatic discharge refers to the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short, or dielectric breakdown. This seemingly minor event can have disastrous consequences in environments where sensitive electronic components are present. ESD is a leading cause of failure in many high-tech devices, including computers, smartphones, and medical equipment.

This is where ESD fabric comes into play. These specialized textiles are designed to prevent the buildup and discharge of static electricity, thereby protecting both workers and equipment. By incorporating conductive materials and anti-static properties, ESD fabric plays a critical role in static-sensitive environments.

ESD fabric works by dissipating electrical charges and preventing the buildup of static electricity. The fabric typically includes conductive fibers, such as carbon, stainless steel, or copper, which help to safely dissipate any static charges that might accumulate on the material. These conductive fibers allow the fabric to reduce the resistance of the material and direct static charges away from sensitive equipment.

The process of controlling electrostatic discharge through fabric involves several key components:

Conductive Fibers: These fibers are woven into the fabric to provide a path for static electricity to flow.

Anti-static Agents: Some ESD fabrics are treated with chemical agents that further enhance their ability to neutralize static charges.

The combination of these materials ensures that any static charge is quickly discharged, protecting both the equipment and personnel in static-sensitive environments.

Blended ESD fabrics are one of the most common types used in the industry. These fabrics are made by blending conductive fibers with traditional textile materials, such as polyester and cotton. The conductive fibers are integrated into the fabric during the manufacturing process, offering a durable and effective solution for static control.

The benefits of blended ESD fabrics include:

Durability: These fabrics maintain their anti-static properties over time, even after repeated washing.

Comfort: By combining traditional fibers with conductive materials, these fabrics are not only effective but also comfortable to wear.

Cost-effectiveness: Blended fabrics are typically more affordable compared to other specialty ESD fabrics, making them a popular choice for general use.

Some ESD fabrics are treated with anti-static coatings or finishes to enhance their performance. These fabrics may be made from non-conductive materials, but the surface is treated with an anti-static agent to prevent static buildup.

Surface Treatment: The treatment applied to the fabric helps to reduce its resistance to static charge buildup, making it a viable option for environments where electrostatic discharge poses a risk.

Use in Cleanrooms: Coated fabrics are particularly popular in cleanroom environments where precise control over static electricity is required to prevent contamination.

These fabrics are less common than blended materials but offer specialized protection for specific applications.

Specialty ESD fabrics are engineered for specific environments that require high levels of static control. These fabrics are often used in industries like aerospace, military, and high-tech electronics, where equipment is extremely sensitive to static charges.

Cleanroom ESD Fabrics: In cleanrooms, where contamination must be kept to an absolute minimum, ESD fabrics play a critical role in maintaining a static-free environment. These fabrics ensure that no static electricity interferes with sensitive electronic parts or contaminates the workspace.

High-Performance Materials: For industries that require superior protection, such as aerospace, specialty fabrics are often made with advanced materials that offer maximum durability and static control.

These fabrics may be engineered with higher conductivity or durability, depending on the industry’s needs.

One of the most important properties of ESD fabric is surface resistance. Surface resistance refers to the ability of a material to resist the flow of electric current along its surface. For an ESD fabric to be effective, its surface resistance should fall within a specific range. Fabrics with too high of a resistance may not be able to dissipate static charges effectively, while fabrics with too low of resistance might allow too much charge to flow, potentially causing a discharge event.

Typically, the ideal surface resistance for ESD fabrics ranges from 10^6 to 10^9 ohms, ensuring that the material can effectively control static without becoming a hazard itself.

Durability is a critical factor when choosing ESD fabric, especially in environments where fabrics are subjected to frequent washing. Many ESD fabrics are designed to be washable, which allows them to maintain their anti-static properties over extended periods. High-quality ESD fabrics will retain their static control performance, even after repeated laundering, making them a cost-effective solution for long-term use.

Long-lasting Protection: ESD fabrics with high durability will continue to protect both workers and equipment over time.

Ease of Maintenance: The ability to wash these fabrics without compromising their performance is essential for industries where hygiene and cleanliness are priorities, such as pharmaceuticals or food production.

ESD fabrics are engineered to remain stable under a variety of environmental conditions, including changes in temperature and humidity. One of the key advantages of ESD fabric is that it maintains its anti-static properties regardless of environmental factors.

Humidity and Temperature Resistance: Unlike other materials that may lose effectiveness in extreme conditions, high-quality ESD fabrics can continue to perform in a range of environments, from humid laboratories to dry factories.

Stable Anti-Static Index: The consistent performance of ESD fabric in varying conditions makes it an ideal solution for industries that rely on static-sensitive equipment, ensuring protection even in the most challenging conditions.

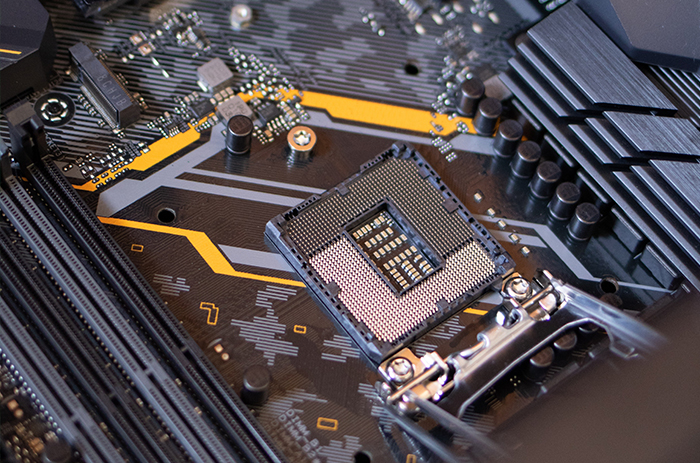

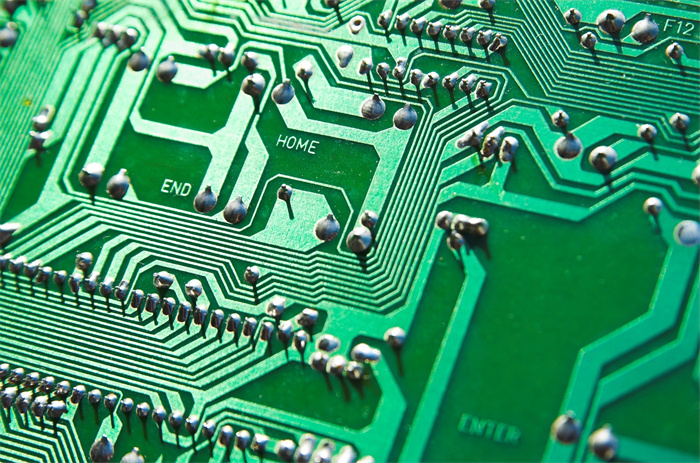

The electronics industry is one of the primary sectors where ESD fabric plays a crucial role. Sensitive electronic components, such as microchips and circuit boards, are highly susceptible to damage from static electricity. Even a small static charge can cause irreparable damage to these delicate devices, leading to costly repairs or replacements.

In this industry, ESD fabrics are used to create protective clothing like smocks, gloves, and shoe covers for workers handling electronic components. Additionally, ESD mats and workstations equipped with ESD fabric are designed to create a safe environment for assembling and testing electronic products. The fabric ensures that any static charge that accumulates on a worker or equipment is dissipated, thus preventing potential damage to the products.

The aerospace and military sectors require the highest standards of static protection. In these fields, electronic components and equipment are extremely sensitive and need to be protected from static-induced failures. ESD fabric plays a critical role in safeguarding critical systems, including avionics, weapons systems, and communication devices.

ESD fabrics used in these industries are often more specialized and engineered to provide superior protection under demanding conditions. For example, aerospace technicians often wear full-body suits made from ESD fabric to prevent electrostatic discharge while working on aircraft. Additionally, high-performance ESD fabrics are used in military applications to prevent static buildup in sensitive equipment, ensuring both safety and functionality in high-stakes environments.

In industries like pharmaceuticals and food production, static electricity can pose a significant risk. Static charges can lead to contamination, either by attracting dust particles or by causing the ignition of flammable substances. In pharmaceutical manufacturing, static electricity can also interfere with the production of sensitive medications.

ESD fabric is commonly used in cleanrooms and controlled environments to prevent the buildup of static charges. Protective clothing made from ESD fabric ensures that workers do not inadvertently introduce contamination into sterile environments. The fabric’s ability to dissipate static charges keeps the working environment safe, protecting both the equipment and the quality of the products being produced.

Cleanrooms require stringent control over environmental factors, including static electricity. In industries where precision is paramount—such as biotechnology, pharmaceuticals, and semiconductors—static discharge can result in catastrophic failures in experiments, contamination of samples, or damage to sensitive equipment.

In these environments, ESD fabrics are essential for creating safe working conditions. Cleanroom suits, gloves, and shoe covers made from ESD fabric are commonly used to protect workers and prevent static buildup. The fabric ensures that workers are grounded, preventing any transfer of static charge to the equipment or materials being handled, which is crucial for maintaining the integrity of sensitive laboratory processes.

In addition to the electronics, aerospace, pharmaceutical, and food industries, ESD fabric has applications in several other sectors where static electricity can cause problems. Industries such as automotive manufacturing, petrochemical processing, mining, and even fireworks production all benefit from the use of ESD fabric.

For example, in automotive manufacturing, workers wear protective clothing made from ESD fabric to prevent static electricity from damaging sensitive parts of vehicles, especially those with electronic components. Similarly, in petrochemical and mining industries, where explosive gases and dust are present, ESD fabric helps prevent the ignition of flammable materials by dissipating static charges safely.

One of the most significant advantages of ESD fabric is its ability to prevent static-induced fires and explosions. In industries dealing with flammable materials, such as chemicals or fuel, the buildup of static electricity can result in disastrous accidents. ESD fabric, by dissipating static charges, reduces the likelihood of sparks that could ignite these hazardous substances.

In environments like petrochemical plants or grain silos, where volatile substances are present, the use of ESD fabric is critical for ensuring worker and environmental safety. By wearing ESD-protective clothing and using ESD mats and workstations, companies can reduce the risk of accidents caused by electrostatic discharge.

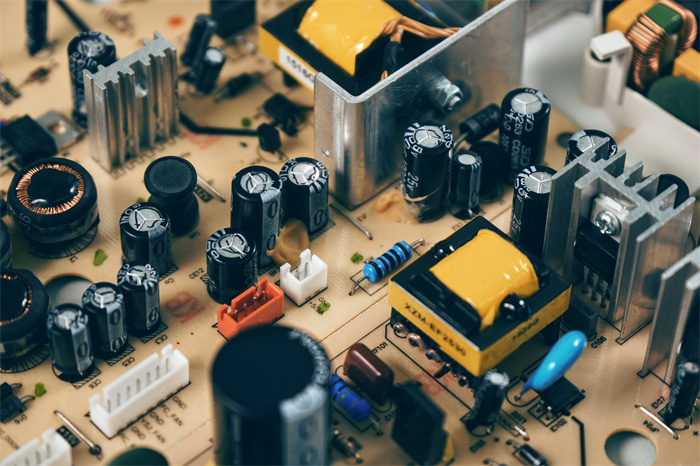

ESD fabric also offers protection for sensitive equipment. In many industries, electronic components, machinery, and devices are designed with tolerances that are extremely sensitive to static electricity. Even a small discharge can result in malfunction or complete failure of the equipment.

Using ESD fabric, companies can protect these valuable assets. Whether through protective clothing, mats, or workstations, ESD fabric helps create environments that prevent static buildup and discharge, extending the lifespan of electronic devices and ensuring reliable performance.

Although ESD fabric may seem like an additional cost, it is actually a highly cost-effective solution in the long run. The use of ESD fabric can significantly reduce the frequency of equipment failure, damage, or accidents caused by static electricity, saving companies a significant amount of money in repairs, replacements, and downtime.

Additionally, ESD fabrics are often washable and reusable, making them a durable and economical choice for long-term protection. Over time, the investment in high-quality ESD fabric can pay off through fewer operational disruptions and a safer work environment.

Worker safety is another important benefit of ESD fabric. In environments where static discharge can lead to both equipment damage and personal injury, wearing ESD-protective clothing is essential. By grounding employees and preventing static buildup, ESD fabric helps protect workers from the dangers associated with static electricity.

In hazardous environments, such as those involving explosive materials or sensitive electronics, ensuring that workers are protected from static discharge is a top priority. ESD fabric plays a vital role in creating a safe working environment, allowing employees to perform their tasks with minimal risk.

The first step in selecting the right ESD fabric is to consider the specific needs of your application. Different industries have varying requirements for static protection, and selecting the right fabric will depend on factors such as environmental conditions, the sensitivity of equipment, and the level of static control needed.

For example, cleanroom environments may require fabrics with a higher level of conductivity and lower surface resistance than general industry applications. Similarly, industries with explosive materials will need to prioritize fabrics that can handle the highest levels of static discharge without compromising safety.

When choosing ESD fabric, it’s essential to consider key specifications such as surface resistance, durability, and washability. These factors will determine how effective the fabric is at controlling static and how long it will continue to perform well under various working conditions.

For example, fabrics with a surface resistance of 10^6 to 10^9 ohms are ideal for most static-sensitive environments, while those designed for extreme conditions may require specialized materials.

Many ESD fabrics come with customization options to suit specific industry needs. Custom sizes, colors, and additional features such as flame-retardant coatings or antimicrobial finishes are available. Tailoring the fabric to meet the exact needs of your environment can enhance its effectiveness in protecting both equipment and personnel.

Ensure that the ESD fabric you select meets the required quality standards and certifications, such as ISO 9001, SGS, and RoHS compliance. These certifications guarantee that the fabric has undergone rigorous testing and adheres to international standards for safety and performance.

Many ESD fabrics are washable, but to maintain their effectiveness over time, proper care is essential. This section could detail the best practices for washing ESD fabrics to ensure their anti-static properties are retained. For instance:

Washing instructions (temperature, detergents to avoid, etc.)

The importance of not using fabric softeners, as they can interfere with conductivity

Drying methods: air drying vs. machine drying

Improper storage of ESD fabrics can reduce their lifespan and effectiveness. Discuss how ESD fabric should be stored in environments where they are not exposed to contamination, extreme temperatures, or physical stress.

Many companies may assume that simply wearing ESD-protective clothing or using ESD mats is sufficient. However, improper use of these materials can still lead to failures. Common mistakes include:

Not grounding personnel or equipment properly

Failing to replace worn-out fabrics

Using ESD materials in environments that exceed their static dissipation limits

Even if workers wear protective clothing, an ESD-safe workspace is crucial. This section can offer guidance on how to create an entire static-controlled environment, with:

ESD mats, workstations, and flooring

ESD wrist straps and other accessories

As the tech industry grows, so does the need for ESD protection. With the increasing prevalence of sensitive technologies like quantum computing, 5G, and wearables, the demand for highly protective ESD fabrics is expected to rise. This section can discuss:

Why ESD fabric is crucial in emerging tech sectors

Specific challenges these technologies face with static electricity

The role of advanced materials in meeting the unique needs of these sectors

As automation and robotics become more widespread across various industries, there will be an increased need for ESD fabric in environments that require precision. Robots and automated systems can be highly sensitive to static charges, making static control even more important.

This section can dive deeper into the future of ESD fabric technology, looking at trends such as:

Smart fabrics integrated with sensors for real-time static monitoring

ESD fabric with improved wear resistance or self-healing properties

The development of environmentally friendly, biodegradable ESD materials

In this conclusion, you can briefly recap the importance of ESD fabric across industries and its crucial role in ensuring safety and equipment protection. Emphasize that choosing the right ESD fabric involves a comprehensive understanding of the environment and application requirements.

As industries continue to prioritize safety and equipment protection, LEENOL stands ready to provide top-tier ESD fabric solutions that meet the highest standards of quality and performance. With our extensive product range and expertise in static control, we are committed to helping you maintain a safe, static-free environment. Whether for cleanrooms, electronics manufacturing, or other critical industries, LEENOL offers reliable, customizable solutions that protect both your personnel and valuable equipment. Reach out to us today to discover how our ESD fabrics can support your operations and help you stay ahead in an increasingly static-sensitive world.

ESD Fabric contains conductive fibers or permanent anti-static treatments that safely dissipate static electricity, while regular fabric cannot control static charge.

ESD Fabric is designed for static-sensitive environments such as electronics and cleanrooms, whereas regular fabric is mainly used for everyday clothing.

A good ESD Fabric should comply with standards such as IEC 61340-5-1 and ANSI/ESD S20.20.

It should have a stable surface resistance (typically 10⁶–10⁹ ohms) and maintain its anti-static performance after repeated washing.

Standard ESD Fabric is not designed for extremely high-temperature environments.

For high-heat or hazardous applications, special ESD fabrics with heat-resistant or flame-retardant materials should be selected according to the actual working conditions.