Views: 496 Author: Site Editor Publish Time: 2026-02-20 Origin: Site

Let’s be honest—electrostatic discharge sounds like a small technical issue. In real factories, however, it quietly causes a lot more trouble than most people expect. A single unnoticed spark can damage micro-components, create hidden product defects, or—worse—become a safety risk in sensitive environments.

That is exactly why ESD fabric has become a basic requirement in modern manufacturing, not just an “extra” layer of protection.

In this article, I will walk you through what ESD fabric really is, how it works, what truly matters when choosing it, and how it is used across real industrial environments today.

In simple terms, ESD fabric is a functional textile designed to control the generation, accumulation, and release of static electricity.

However, calling it “anti-static fabric” is slightly misleading.

Ordinary fabrics—cotton, polyester, nylon—can easily build up electrical charges through daily movements such as walking, sitting, lifting parts, or brushing against packaging. The problem is not the charge itself. The problem is that the charge has no controlled way to escape.

ESD fabric is engineered to provide a predictable and stable dissipation path for those charges.

Instead of allowing energy to accumulate and suddenly discharge, the fabric guides charges away in a slow and controlled manner. In other words, ESD fabric does not fight physics—it manages it.

Here is the key idea—and honestly, it is much simpler than it sounds.

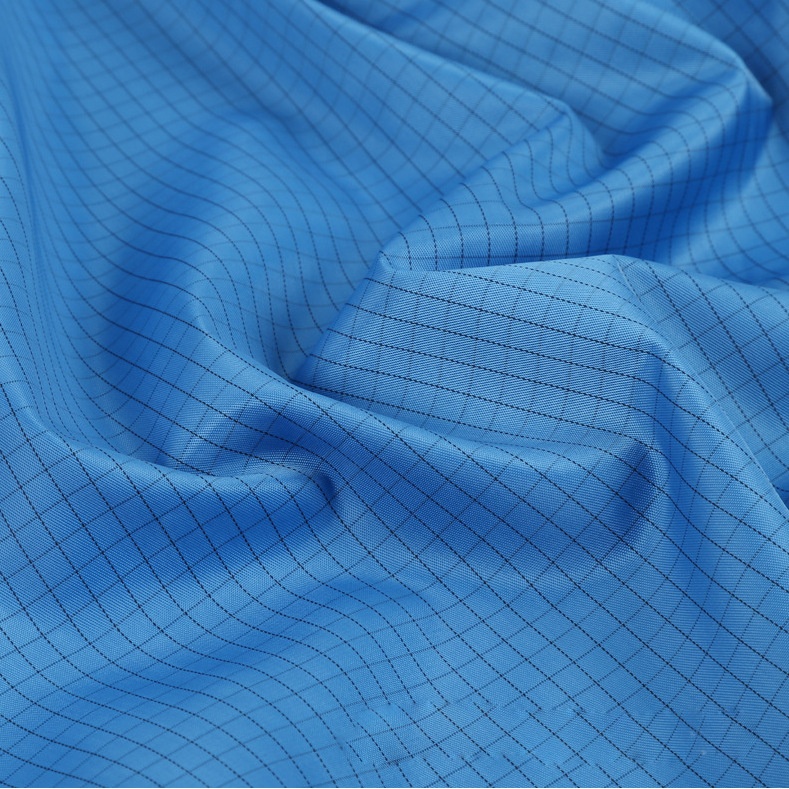

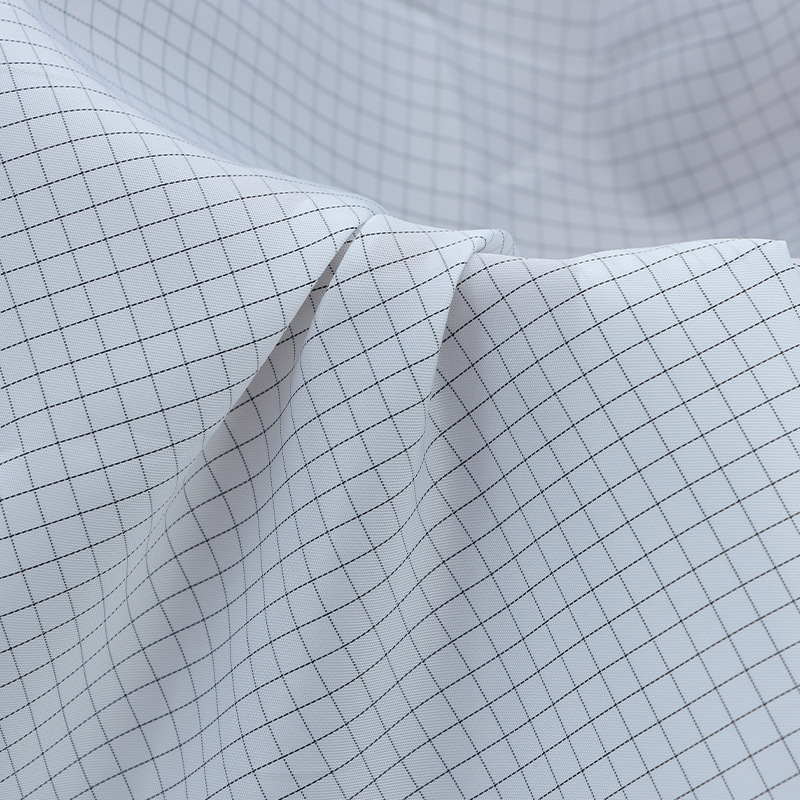

Modern ESD fabrics integrate extremely fine conductive fibers into the textile structure. These fibers may be carbon-based, metal-coated, or composite conductive filaments. They are arranged in regular stripe or grid patterns throughout the fabric.

When static charges are created on the garment surface:

the charges are attracted to the conductive fibers,

the fibers distribute the charges across the fabric,

the charges are slowly transferred to ground through footwear, flooring, or grounding systems.

This is what people mean by controlled dissipation.

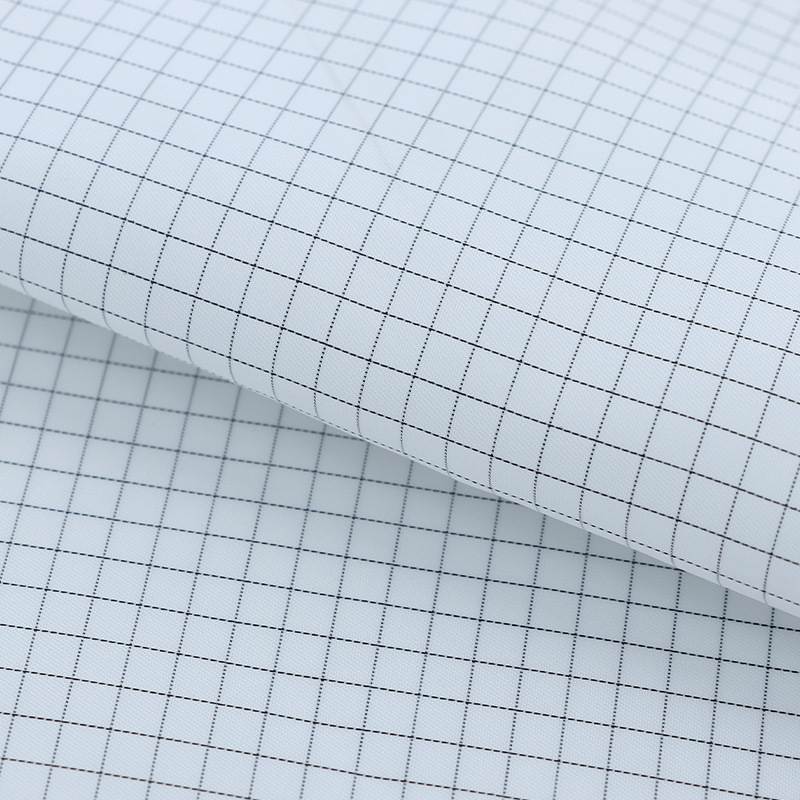

And yes, this is important: the conductive network is permanent. It is part of the fabric itself. It does not wash out, and it does not rely on humidity to work properly.

In real production environments, ESD fabrics are generally manufactured using three technical approaches.

This is, without question, the most reliable and widely accepted technology today.

Conductive fibers are introduced during yarn production or directly woven into the fabric structure. The resulting fabric forms a stable electrical network.

This method is especially suitable for:

reusable cleanroom garments,

semiconductor production clothing,

long-life industrial workwear.

The biggest advantage is durability. After repeated washing cycles, the fabric still performs as designed.

This approach applies chemical anti-static agents to the fabric surface after weaving.

It works—at first.

But in practice, performance gradually drops after laundering and long-term use. For light-duty environments this may be acceptable. For controlled production zones, it usually is not.

Some advanced textiles use chemically modified fibers to improve charge mobility. These solutions are more specialized and less common in everyday ESD garments.

In most professional ESD programs, conductive fiber blending remains the technical backbone.

When engineers evaluate ESD fabrics, they do not start with color or softness. They start with numbers.

ESD garments are designed to fall into a controlled dissipation range. Typical industrial fabrics operate roughly between:

10⁴ and 10⁹ ohms

This range allows static charges to be released safely without turning the garment into a highly conductive element.

A high-quality ESD fabric should perform consistently:

in dry winter conditions,

in humid production halls,

under temperature fluctuations.

This stability matters more than many people realize, especially in global factories with very different climates.

Here is a practical reality: industrial garments are washed frequently.

If the conductive network degrades, the garment becomes a risk rather than a solution. Long-term wash resistance is therefore one of the most important performance indicators.

Two structures dominate industrial ESD fabrics.

Conductive yarns run in parallel lines, often with 5 mm spacing.

Stripe fabrics are commonly used for:

electronics assembly lines,

laboratory coats,

general ESD uniforms.

They are effective, economical, and visually clean.

Conductive yarns form a square network in both directions.

This structure offers:

more uniform charge distribution,

better consistency over the entire garment,

improved reliability in high-risk areas.

Grid designs are typically selected for advanced cleanrooms and semiconductor production.

ESD protection is essential—but people still have to wear the garments all day.

Polyester provides:

low particle generation,

good mechanical strength,

excellent compatibility with conductive yarns.

This is why polyester-based ESD fabrics dominate cleanroom environments.

Blended fabrics introduce cotton to improve:

softness,

moisture absorption,

thermal comfort.

These fabrics are widely used in laboratories and inspection areas where comfort directly affects operator compliance.

Here is something that is often underestimated.

Many ESD failures are latent. Components pass testing. Products ship. Failures appear weeks or months later. Tracking the root cause becomes extremely difficult.

ESD garments reduce one of the most unstable variables in the process—the human body. They significantly lower the probability that operators themselves become uncontrolled charge sources.

In safety-critical environments, this is not just about yield. It is about risk management.

This is still the core application.

ESD fabrics are used in:

cleanroom coveralls,

ESD jackets,

laboratory coats,

operator uniforms.

They protect highly sensitive components such as ICs, sensors, and memory devices.

ESD fabrics reduce static attraction of particles and support contamination control in cleanrooms. Their low-lint properties and wash durability are critical.

Assembly and testing of complex electronic systems demand stable and predictable static control. ESD garments support both equipment protection and operator safety.

In areas with flammable vapors or powders, reducing static accumulation on clothing is a fundamental safety requirement.

Selecting ESD fabric should be a structured decision.

Not every workstation requires the same level of protection. Cleanrooms, repair benches, and chemical handling zones all differ significantly.

If garments are washed industrially, conductive fiber fabrics offer much better long-term stability.

This may sound secondary—but it is not. Comfortable garments are worn correctly. Poorly designed garments are not.

ESD fabric alone does not create an ESD program.

It must work together with:

ESD footwear,

conductive flooring,

grounded workstations,

packaging materials,

ionizers.

Only as part of an integrated system does ESD fabric deliver its full value.

Manufacturers increasingly expect stable performance after many washing cycles.

Improved comfort reduces fatigue and increases compliance during long shifts.

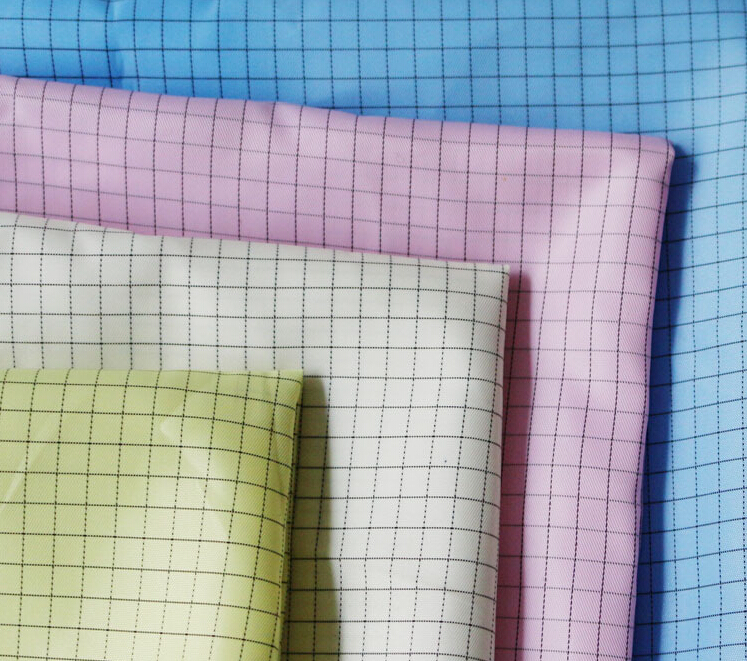

Factories now request specific colors, logos, and layouts to support identification and process control.

To be practical, strong fabrics alone are not enough. Real projects require consistent quality, reliable supply, and technical support.

LEENOL focuses on providing industrial-grade ESD fabrics based on stable conductive fiber technologies. The company supplies polyester and polyester-cotton ESD fabrics, stripe and grid structures, and supports flexible customization for garment manufacturers and end users.

By serving industries such as electronics, pharmaceuticals, aerospace, and chemical processing, LEENOL helps customers build dependable static control systems that actually work on the production floor—not only on paper.

1. Is ESD fabric the same as ordinary anti-static fabric?

Not exactly. Ordinary anti-static fabrics often rely on surface treatments, while true ESD fabrics use integrated conductive fibers to create controlled and durable charge dissipation.

2. Can ESD fabric completely eliminate static electricity?

No. It controls how charges move and dissipate. It significantly reduces risk but does not stop charge generation entirely.

3. How long does ESD fabric remain effective?

High-quality conductive fiber ESD fabrics remain effective throughout the service life of the garment when properly laundered.

4. Should I always choose grid fabric instead of stripe fabric?

Not necessarily. Grid fabrics offer more uniform dissipation, but stripe fabrics are fully suitable for many standard electronics and laboratory environments.

5. Can ESD fabric be customized?

Yes. Color, pattern spacing, fabric weight, and composition can be customized according to operational and branding requirements.