| Material: | Type: |

| Plastic | Tray packaging |

| Plastic Type: | material: |

| PP | eco-friendly |

| Process Type: | usage: |

| Blister | packing and transport |

| Custom Order: | Color: |

| Accept | Customized |

| Place of Origin: | Size: |

| Guangdong, China | Customized Size |

| Brand Name: | Logo: |

| ksm | Customer's Logo |

| Model Number: | Thickness: |

| ksmt-t0101 | 0.25mm~1.5mm |

| Use: | Certificate: |

| Electronic | ISO9001:2008 |

| Blister trays: | Plastic trays: |

| ESD tray | PP tray |

LN-1012DLE

LEENOL

| Material: | |

|---|---|

| weight(gsm): | |

| size: | |

| packing /bag: | |

| bags/carton: | |

| Availability: | |

| Quantity: | |

| Product Description | |

| 1, They are comprised of 100% polyester continuous filament polyester in a straight-knit pattern with laser sealed edge | |

| 2, Highly absorbent with extremely low levels of particulate and extractable counts. | |

| 3, Laundered and packaged in a cleanroom | |

| 4, Tested and manufactured in ISO compliant facilities | |

| Features: | |

| 1. 18MΩ pure water laundered, clean room class10, 000-10 packing. | |

| 2. Soft and no harmful to wiped surface. | |

| 3. High efficient absorbency | |

| 4. Ultro-low particle and dust generation. Remark: Can be medical used after sterilization or be added with alcohol, IPA solutions and so on. | |

| Applications | |

| 1) It is designed for critical processing applications where the high level of contamination control is required. | |

| 2) It is widely used for cleaning in industry of Clean room, Semi-conductor, TFT, LCD, micro-electronics, integrated circuit,precision instrument, PCB, SMT, medical, lab and aviation etc |

Cleanroom cloth wipe

● GOOD WATER ABSORPTION,HIGH CLEANLINESS LEAVE NO TRACE

● GOOD DUSTING,HIGH SORPTIVE CAPACITY,LIGHTER WEIGHT

● SUPERB SOFTNESS,100% POLYESTER NO PILLING

● OIL ABSORPTION,DECONTAMINATION KEEP OBJECTS BRIGHT

| Product Description | |

| 1, They are comprised of 100% polyester continuous filament polyester in a straight-knit pattern with laser sealed edge | |

| 2, Highly absorbent with extremely low levels of particulate and extractable counts. | |

| 3, Laundered and packaged in a cleanroom | |

| 4, Tested and manufactured in ISO compliant facilities | |

| Features: | |

| 1. 18MΩ pure water laundered, clean room class10, 000-10 packing. | |

| 2. Soft and no harmful to wiped surface. | |

| 3. High efficient absorbency | |

| 4. Ultro-low particle and dust generation. Remark: Can be medical used after sterilization or be added with alcohol, IPA solutions and so on. | |

| Applications | |

| 1) It is designed for critical processing applications where the high level of contamination control is required. | |

| 2) It is widely used for cleaning in industry of Clean room, Semi-conductor, TFT, LCD, micro-electronics, integrated circuit,precision instrument, PCB, SMT, medical, lab and aviation etc |

Cleanroom cloth wipe

● GOOD WATER ABSORPTION,HIGH CLEANLINESS LEAVE NO TRACE

● GOOD DUSTING,HIGH SORPTIVE CAPACITY,LIGHTER WEIGHT

● SUPERB SOFTNESS,100% POLYESTER NO PILLING

● OIL ABSORPTION,DECONTAMINATION KEEP OBJECTS BRIGHT

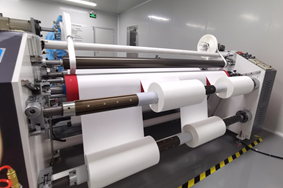

Factory

Adhering to a scientific and reasonable production layout,The total area of our three factory workshops is 16,000 square meters.It is currently a large-scale dust-free company in the entire industry chain Wipers manufacturer. There are about 300 employees in the three fact ories. Among them, 5 texturing threads. 50 knitting machines and 20 shuttle looms. It has its own dyeing and finishing line. 15 laser machi nes. 6 hot cutting machines. 6 ultrasonic cuttng machines. A set of 10 tons of pure water system, a standard 100-level workshop.

Production capacity: DTY polyester silk yarn 300 tons/month, raw wiper material 350-400 t ons/month, dust-free wiping wiper 300,000 packs/month. Reel wiper 200,000 rolls/month.

1.Chemical fiber yarn texturing

2.Knitted fabric

3.Woven workshop

4.Loose fabric

5.Washing, dyeing and finishing

6.High-temperature shaping

7.Inspection cloth roll

8.Finished fabric raw material

9.laser cutting

10.Ultrasonic cross sectioning

11.EDI pure water system

12.Slitting

13.Slitting

14.Standard 100-level workshop

15.Vacuum packaging

16.Packed and shipped

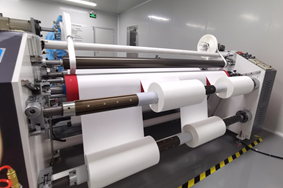

Factory

Adhering to a scientific and reasonable production layout,The total area of our three factory workshops is 16,000 square meters.It is currently a large-scale dust-free company in the entire industry chain Wipers manufacturer. There are about 300 employees in the three fact ories. Among them, 5 texturing threads. 50 knitting machines and 20 shuttle looms. It has its own dyeing and finishing line. 15 laser machi nes. 6 hot cutting machines. 6 ultrasonic cuttng machines. A set of 10 tons of pure water system, a standard 100-level workshop.

Production capacity: DTY polyester silk yarn 300 tons/month, raw wiper material 350-400 t ons/month, dust-free wiping wiper 300,000 packs/month. Reel wiper 200,000 rolls/month.

1.Chemical fiber yarn texturing

2.Knitted fabric

3.Woven workshop

4.Loose fabric

5.Washing, dyeing and finishing

6.High-temperature shaping

7.Inspection cloth roll

8.Finished fabric raw material

9.laser cutting

10.Ultrasonic cross sectioning

11.EDI pure water system

12.Slitting

13.Slitting

14.Standard 100-level workshop

15.Vacuum packaging

16.Packed and shipped

● Q1: Are you a manufacturer?

①.Ans:Yes, we have been in manufacturing and providing excellent Cleanroom and ESD solutions for customers more than 10years.

②.Our own production plants and a wide network of suppliers who are strictly selected, are totally qualified for ISO Quality Management System.

● Q2: How long could you prepare samples?

Ans:Normally 1days if we have the sample onhand. If customized one, about a week around.

● Q3: How about batch order production?

Ans: Normally 3-7days or so

● Q4: Do you inspect the finished products?

Ans:Yes, we will do inspection according to ISO standard and ruled by our QC staff.

● Q5: How do you ship the goods?

Ans: By sea, by air, by truck or by courier (UPS, DHL, Fedex, TNT etc.)

● Q6: What advantage do you have?

Ans:

①.We have professional engineers, customers can expect the best possible advice and support.

②.Related responsible team to answer all your questions and follow-up process for you and do update in time

③.Strict and standard process control according to Quality Management System.

④.Documents support on products, we have strong technical data sheet to support our products, which could make you easier to know our products.

● Q1: Are you a manufacturer?

①.Ans:Yes, we have been in manufacturing and providing excellent Cleanroom and ESD solutions for customers more than 10years.

②.Our own production plants and a wide network of suppliers who are strictly selected, are totally qualified for ISO Quality Management System.

● Q2: How long could you prepare samples?

Ans:Normally 1days if we have the sample onhand. If customized one, about a week around.

● Q3: How about batch order production?

Ans: Normally 3-7days or so

● Q4: Do you inspect the finished products?

Ans:Yes, we will do inspection according to ISO standard and ruled by our QC staff.

● Q5: How do you ship the goods?

Ans: By sea, by air, by truck or by courier (UPS, DHL, Fedex, TNT etc.)

● Q6: What advantage do you have?

Ans:

①.We have professional engineers, customers can expect the best possible advice and support.

②.Related responsible team to answer all your questions and follow-up process for you and do update in time

③.Strict and standard process control according to Quality Management System.

④.Documents support on products, we have strong technical data sheet to support our products, which could make you easier to know our products.