| Material: | Type: |

| Plastic | Tray packaging |

| Plastic Type: | material: |

| PP | eco-friendly |

| Process Type: | usage: |

| Blister | packing and transport |

| Custom Order: | Color: |

| Accept | Customized |

| Place of Origin: | Size: |

| Guangdong, China | Customized Size |

| Brand Name: | Logo: |

| ksm | Customer's Logo |

| Model Number: | Thickness: |

| ksmt-t0101 | 0.25mm~1.5mm |

| Use: | Certificate: |

| Electronic | ISO9001:2008 |

| Blister trays: | Plastic trays: |

| ESD tray | PP tray |

LN-1601006S

LEENOL

| Material: | |

|---|---|

| weight(gsm): | |

| size: | |

| packing /bag: | |

| bags/carton: | |

| Availability: | |

| Quantity: | |

The LN-1601006S Cleanroom Wiper is a premium 100% polyester, double-knit, ultra-soft dust-free wipe cloth engineered for controlled environments such as cleanrooms, laboratories, semiconductor facilities and precision manufacturing.

Each wiper is manufactured using a laser-sealed edge to minimize loose fibers and particulate contamination. The fabric provides excellent absorbency, chemical resistance and low particle generation, making it ideal for sensitive cleaning processes.

| Parameter | Details |

|---|---|

| Model | LN-1601006S |

| Material | 100% Polyester (Double-Knit) |

| Edge Type | Laser-Sealed Edge |

| Texture | Ultra-Soft, Low-Lint |

| Size | 6 × 6 in (150 × 150 mm) |

| GSM (Weight) | 120–140 g/m² |

| Cleanroom Compatibility | ISO Class 100–1000 (Class 5–7) |

| Absorbency | High liquid absorption, rapid uptake |

| Chemical Resistance | Compatible with IPA & common solvents |

| Packaging | 100 pcs/bag, double-layer clean packing |

| Applications | Cleanroom surface wiping, equipment cleaning, electronics, optics, precision instruments |

Ultra-soft 100% polyester for scratch-free cleaning on sensitive surfaces

Laser-sealed edges dramatically reduce loose fibers and particle shedding

Extremely low ionic contamination suitable for microelectronics

High absorbency for effective solvent wiping (IPA, acetone, etc.)

Excellent chemical compatibility for cleanroom solvents and disinfectants

Q1: Is the LN-1601006S cleanroom wiper suitable for Class 100 cleanrooms?

Yes. The LN-1601006S polyester cleanroom wiper is compatible with ISO Class 100–1000 cleanroom environments, offering extremely low-lint performance.

Q2: Can the polyester cleanroom wiper be used with IPA or solvents?

Absolutely. 100% polyester wipers have excellent chemical resistance and work well with IPA, ethanol and most cleanroom-grade solvents.

Q3: What makes this cleanroom wiper low-lint?

The wiper is produced with a laser-sealed edge and double-knit polyester structure, minimizing fiber release and preventing contamination during sensitive cleaning operations.

The LN-1601006S Cleanroom Wiper is a premium 100% polyester, double-knit, ultra-soft dust-free wipe cloth engineered for controlled environments such as cleanrooms, laboratories, semiconductor facilities and precision manufacturing.

Each wiper is manufactured using a laser-sealed edge to minimize loose fibers and particulate contamination. The fabric provides excellent absorbency, chemical resistance and low particle generation, making it ideal for sensitive cleaning processes.

| Parameter | Details |

|---|---|

| Model | LN-1601006S |

| Material | 100% Polyester (Double-Knit) |

| Edge Type | Laser-Sealed Edge |

| Texture | Ultra-Soft, Low-Lint |

| Size | 6 × 6 in (150 × 150 mm) |

| GSM (Weight) | 120–140 g/m² |

| Cleanroom Compatibility | ISO Class 100–1000 (Class 5–7) |

| Absorbency | High liquid absorption, rapid uptake |

| Chemical Resistance | Compatible with IPA & common solvents |

| Packaging | 100 pcs/bag, double-layer clean packing |

| Applications | Cleanroom surface wiping, equipment cleaning, electronics, optics, precision instruments |

Ultra-soft 100% polyester for scratch-free cleaning on sensitive surfaces

Laser-sealed edges dramatically reduce loose fibers and particle shedding

Extremely low ionic contamination suitable for microelectronics

High absorbency for effective solvent wiping (IPA, acetone, etc.)

Excellent chemical compatibility for cleanroom solvents and disinfectants

Q1: Is the LN-1601006S cleanroom wiper suitable for Class 100 cleanrooms?

Yes. The LN-1601006S polyester cleanroom wiper is compatible with ISO Class 100–1000 cleanroom environments, offering extremely low-lint performance.

Q2: Can the polyester cleanroom wiper be used with IPA or solvents?

Absolutely. 100% polyester wipers have excellent chemical resistance and work well with IPA, ethanol and most cleanroom-grade solvents.

Q3: What makes this cleanroom wiper low-lint?

The wiper is produced with a laser-sealed edge and double-knit polyester structure, minimizing fiber release and preventing contamination during sensitive cleaning operations.

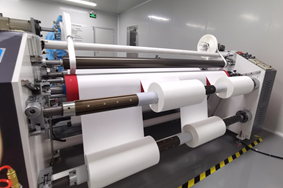

Factory

Adhering to a scientific and reasonable production layout,The total area of our three factory workshops is 16,000 square meters.It is currently a large-scale dust-free company in the entire industry chain Wipers manufacturer. There are about 300 employees in the three fact ories. Among them, 5 texturing threads. 50 knitting machines and 20 shuttle looms. It has its own dyeing and finishing line. 15 laser machi nes. 6 hot cutting machines. 6 ultrasonic cuttng machines. A set of 10 tons of pure water system, a standard 100-level workshop.

Production capacity: DTY polyester silk yarn 300 tons/month, raw wiper material 350-400 t ons/month, dust-free wiping wiper 300,000 packs/month. Reel wiper 200,000 rolls/month.

1.Chemical fiber yarn texturing

2.Knitted fabric

3.Woven workshop

4.Loose fabric

5.Washing, dyeing and finishing

6.High-temperature shaping

7.Inspection cloth roll

8.Finished fabric raw material

9.laser cutting

10.Ultrasonic cross sectioning

11.EDI pure water system

12.Slitting

13.Slitting

14.Standard 100-level workshop

15.Vacuum packaging

16.Packed and shipped

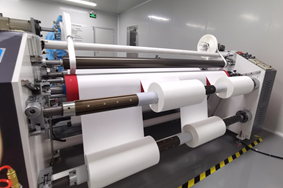

Factory

Adhering to a scientific and reasonable production layout,The total area of our three factory workshops is 16,000 square meters.It is currently a large-scale dust-free company in the entire industry chain Wipers manufacturer. There are about 300 employees in the three fact ories. Among them, 5 texturing threads. 50 knitting machines and 20 shuttle looms. It has its own dyeing and finishing line. 15 laser machi nes. 6 hot cutting machines. 6 ultrasonic cuttng machines. A set of 10 tons of pure water system, a standard 100-level workshop.

Production capacity: DTY polyester silk yarn 300 tons/month, raw wiper material 350-400 t ons/month, dust-free wiping wiper 300,000 packs/month. Reel wiper 200,000 rolls/month.

1.Chemical fiber yarn texturing

2.Knitted fabric

3.Woven workshop

4.Loose fabric

5.Washing, dyeing and finishing

6.High-temperature shaping

7.Inspection cloth roll

8.Finished fabric raw material

9.laser cutting

10.Ultrasonic cross sectioning

11.EDI pure water system

12.Slitting

13.Slitting

14.Standard 100-level workshop

15.Vacuum packaging

16.Packed and shipped

● Q1: Are you a manufacturer?

①.Ans:Yes, we have been in manufacturing and providing excellent Cleanroom and ESD solutions for customers more than 10years.

②.Our own production plants and a wide network of suppliers who are strictly selected, are totally qualified for ISO Quality Management System.

● Q2: How long could you prepare samples?

Ans:Normally 1days if we have the sample onhand. If customized one, about a week around.

● Q3: How about batch order production?

Ans: Normally 3-7days or so

● Q4: Do you inspect the finished products?

Ans:Yes, we will do inspection according to ISO standard and ruled by our QC staff.

● Q5: How do you ship the goods?

Ans: By sea, by air, by truck or by courier (UPS, DHL, Fedex, TNT etc.)

● Q6: What advantage do you have?

Ans:

①.We have professional engineers, customers can expect the best possible advice and support.

②.Related responsible team to answer all your questions and follow-up process for you and do update in time

③.Strict and standard process control according to Quality Management System.

④.Documents support on products, we have strong technical data sheet to support our products, which could make you easier to know our products.

● Q1: Are you a manufacturer?

①.Ans:Yes, we have been in manufacturing and providing excellent Cleanroom and ESD solutions for customers more than 10years.

②.Our own production plants and a wide network of suppliers who are strictly selected, are totally qualified for ISO Quality Management System.

● Q2: How long could you prepare samples?

Ans:Normally 1days if we have the sample onhand. If customized one, about a week around.

● Q3: How about batch order production?

Ans: Normally 3-7days or so

● Q4: Do you inspect the finished products?

Ans:Yes, we will do inspection according to ISO standard and ruled by our QC staff.

● Q5: How do you ship the goods?

Ans: By sea, by air, by truck or by courier (UPS, DHL, Fedex, TNT etc.)

● Q6: What advantage do you have?

Ans:

①.We have professional engineers, customers can expect the best possible advice and support.

②.Related responsible team to answer all your questions and follow-up process for you and do update in time

③.Strict and standard process control according to Quality Management System.

④.Documents support on products, we have strong technical data sheet to support our products, which could make you easier to know our products.