Views: 468 Author: Site Editor Publish Time: 2026-01-16 Origin: Site

Maintaining a sterile and contamination‑controlled environment is foundational to the success of modern manufacturing processes — especially in industries like pharmaceuticals, biotechnology, electronics, and medical devices. Cleanroom wipers are more than just cleaning cloths; they are essential tools for contamination control in environments where even microscopic particles or microbes can cause product defects, compromise sterility, or result in costly recalls.

This article explores the role of cleanroom wipers in maintaining sterile conditions, details their applications and benefits, explains how they help meet strict industry standards, and offers guidance on selecting and using the right wipers for your manufacturing environment.

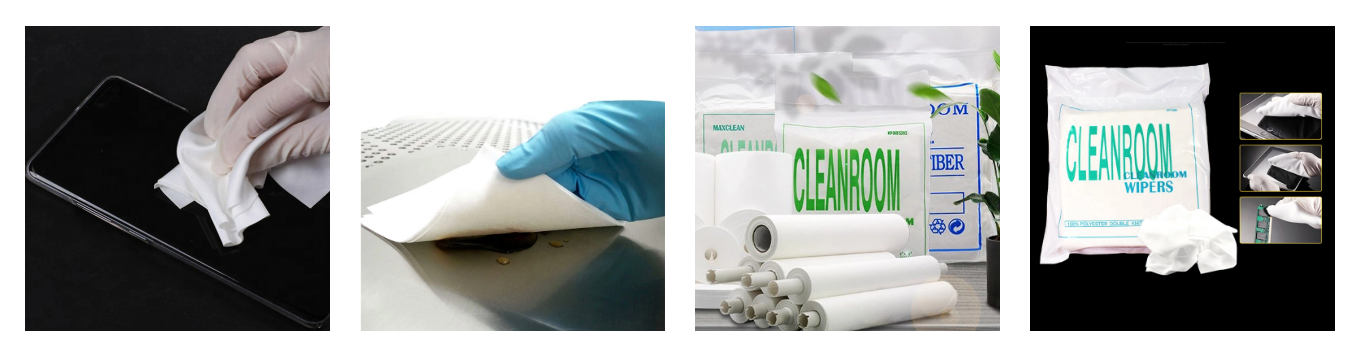

Cleanroom wipers, also called cleanroom wipes, are specialized wiping materials manufactured and processed to meet strict cleanliness requirements. Unlike ordinary cleaning cloths, cleanroom wipers are engineered to minimize particle shedding, fiber release, and chemical residue, ensuring they do not introduce contamination into controlled environments.

They are used to:

Remove particulate matter and microscopic contamination from surfaces

Clean liquid spills without leaving residues

Support sterile procedures and aseptic manufacturing

Aid in routine contamination control practices

Regular wipes often shed fibers, particles, or leave residues — unacceptable in a cleanroom where even a small contaminant can compromise manufacturing quality. Cleanroom wipers, by contrast, are made from low‑lint and low‑particle materials, and are often specially treated or sterilized for sensitive environments.

A cleanroom is a controlled area designed to maintain very low concentrations of airborne particles and, when necessary, microorganisms. Cleanrooms are used where products or processes are highly sensitive to contamination — such as semiconductor fabrication, drug production, medical device assembly, and biotechnology research.

Cleanrooms are classified by standards (e.g., ISO 14644), which define the allowable limits of particles per unit volume of air. Strict environmental controls, filtration systems (e.g., HEPA), airflow management, and contamination control procedures are essential in these spaces.

In sterile manufacturing, contamination control is non‑negotiable. Whether manufacturing injectable drugs or implantable medical devices, maintaining sterility protects product quality and patient safety. Even a single particle or viable microbe can ruin a batch or cause a harmful outcome. Cleanroom consumables, including wipers, play a critical role in controlling contamination at every stage.

Cleanroom wipers are engineered to produce minimal particle and fiber shedding, compared to conventional wipes. Their manufacturing process and material composition — often involving polyester, microfiber, or hydroentangled non‑woven structures — reduce the risk of particles becoming airborne or deposited on critical surfaces.

This is especially crucial in sterile environments where:

Surface contamination must be tightly controlled

Microscopic particles could interfere with chemical reactions, bonding processes, or optical surfaces

Even trace contaminants can compromise sterility compliance

In cleanrooms and sterile zones, spills of liquids such as isopropyl alcohol (IPA), solvents, or biochemical fluids must be efficiently removed. Cleanroom wipers are designed to absorb liquids deeply and evenly without leaving streaks, residue, or re‑deposition of contaminants. This ensures that cleaning contributes to contamination control rather than undermines it.

Certain cleanroom wipers are sterile or pre‑wetted with disinfectants to further support aseptic processes. In pharmaceutical or biotechnology environments, sterile wipes may be used to wipe down gloves, equipment, pass‑through surfaces, or packaging before entry into the most critical zones. In these cases, the wipe itself becomes part of the sterile barrier method, helping prevent viable microbes from entering sensitive areas.

Cleanroom wipers are used wherever contamination control is essential. Some of the key industries and applications include:

Sterile drug production and biologics

Aseptic fill finish processes

Equipment and surface sanitization before critical operations

Maintaining sterility is crucial to ensure product safety, regulatory compliance, and therapeutic efficacy in these sectors.

Even microscopic particles can cause defects in microchips and sensors. Cleanroom wipers ensure that production surfaces, test benches, and critical tools remain free from contamination to maximize yields and performance.

Medical devices often interact with the human body; therefore, sterility and contamination control are essential to manufacturing processes to prevent infection risks. Cleanroom wipers help maintain controlled conditions during assembly and inspection processes.

In industries where precision is paramount, cleanroom wipers are used to clean surfaces, lenses, and components where any particulate could undermine functionality or reliability.

Dry wipes are typically used for general surface cleaning and removal of contaminants, while pre‑wetted wipers are impregnated with controlled cleaning solutions (e.g., IPA) to facilitate more effective decontamination and reduce steps in cleaning protocols.

Sterile pre‑wetted wipers can be especially valuable in sterile suites, where wiping techniques must also incorporate disinfection of surfaces and equipment without introducing new sources of contamination.

Sterile wipes undergo manufacturing processes and sterilization treatments to meet stringent cleanroom validation requirements, ensuring they themselves do not introduce microorganisms into aseptic environments.

Different cleanroom classifications demand different levels of control. Wipers must match the ISO class and regulatory requirements of your environment. Choosing the wrong wipe can introduce particles, compromise sterility, or fail to remove residues efficiently.

Correct wiping technique — including fold and wipe patterns, avoiding re‑deposition, and ensuring complete surface coverage — enhances cleaning effectiveness and reduces contamination risks.

In aseptic or sterile processing areas, use certified sterile wipes to minimize introduction of viable contamination. This careful selection supports regulatory compliance (e.g., GMP, ISO) and helps avoid costly production failures or audit issues.

By effectively removing contaminants, cleanroom wipers help maintain consistent production quality, reduce defects, and improve overall yields. This is vital in high‑precision sectors where rework or scrap can be extremely costly.

Using appropriate cleanroom wipers helps companies comply with ISO cleanroom standards, GMP regulations, and other industry specific requirements — reducing risks during audits and product inspections.

While high‑end cleanroom wipers may cost more upfront than generic cleaning materials, their ability to prevent contamination and preserve product integrity often leads to lower long‑term operational costs and fewer disruptions.

Cleanroom wipers are indispensable for maintaining sterile and contamination‑controlled manufacturing environments. From preventing particulate and chemical contamination to supporting sterile processes and meeting strict regulatory standards, these specialized wipes play a central role in protecting product quality, ensuring compliance, and safeguarding patient and user safety.

In critical applications — whether pharmaceutical manufacturing, medical device production, or semiconductor fabrication — choosing the right cleanroom wiper and using it correctly is just as important as air filtration systems or controlled access procedures.

At LEENOL, we provide a complete range of high‑quality cleanroom wipers designed to meet the stringent requirements of sterile manufacturing environments. Our cleanroom wipers are engineered for ultra‑low particle generation, high absorbency, and compatibility with strict GMP and ISO standards — helping you maintain the highest levels of contamination control and operational efficiency. Partner with LEENOL for tailored cleanroom solutions that enhance product quality and meet your most demanding cleanroom requirements.

1. What makes cleanroom wipers different from regular cleaning wipes?

Cleanroom wipers are manufactured and processed under controlled conditions to minimize particle shedding and chemical residues, making them suitable for contamination‑sensitive environments.

2. Can cleanroom wipers be used in sterile pharmaceutical manufacturing?

Yes — sterile cleanroom wipers are specifically designed for use in aseptic environments to help maintain sterility and meet regulatory standards.

3. How do I choose the right cleanroom wiper for my facility?

Consider your cleanroom class, required sterility levels, absorbency needs, and the types of contaminants you need to control.

4. Why are pre‑wetted cleanroom wipers useful?

Pre‑wetted wipes are impregnated with controlled cleaning solutions that help sanitize and clean surfaces more consistently than dry wipes alone.

5. Do cleanroom wipers help with regulatory compliance?

Yes — using the appropriate cleanroom wipers helps support compliance with ISO cleanroom classifications and GMP requirements.